Rilco Cam Rollers (RCR)

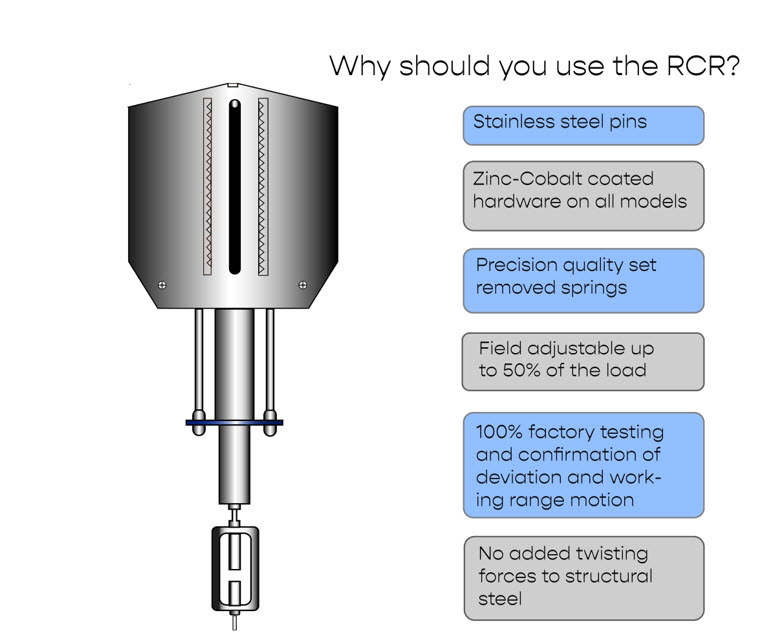

Design Features

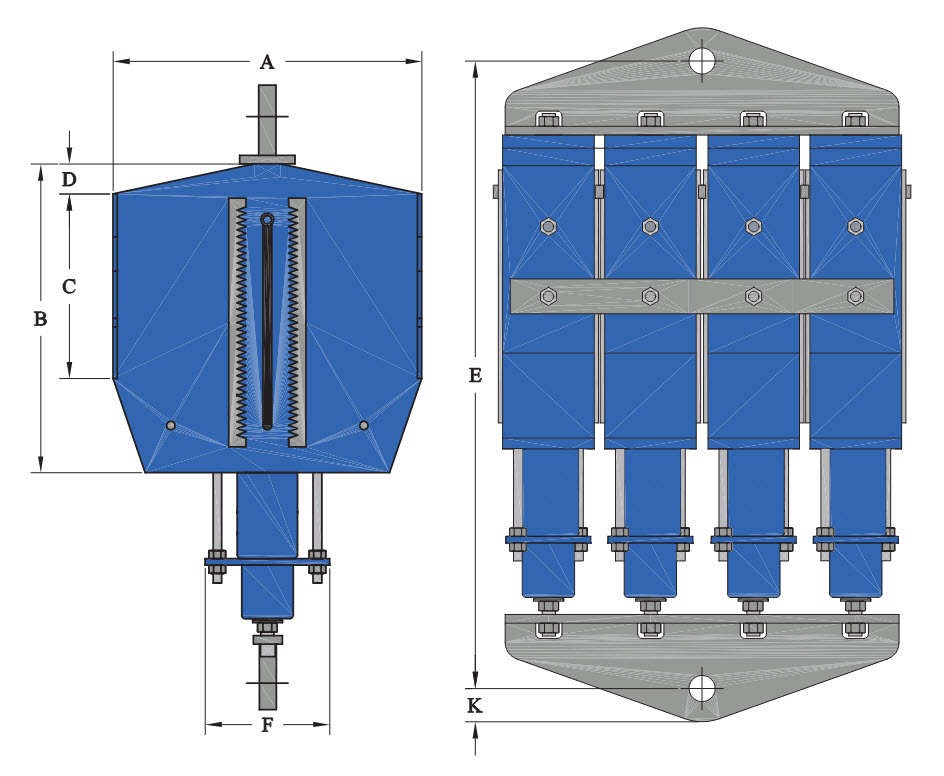

RCR constants are fabricated utilizing a space saving, balanced design which utilizes standard Rilco hang- er hardware. Site installation is enhanced via the use of the centered, single point connection. RCR constants transfer the load directly through the center of the body, eliminating the moment imposed on the supporting members typically seen with the use standard lever arm constants. The interpretation of the vertical displacement of the supported piping is made simpler through the use of a direct reading travel indicator.

Construction

A rugged carbon steel housing encapsulates the springs and other moving parts of the unit. The center-

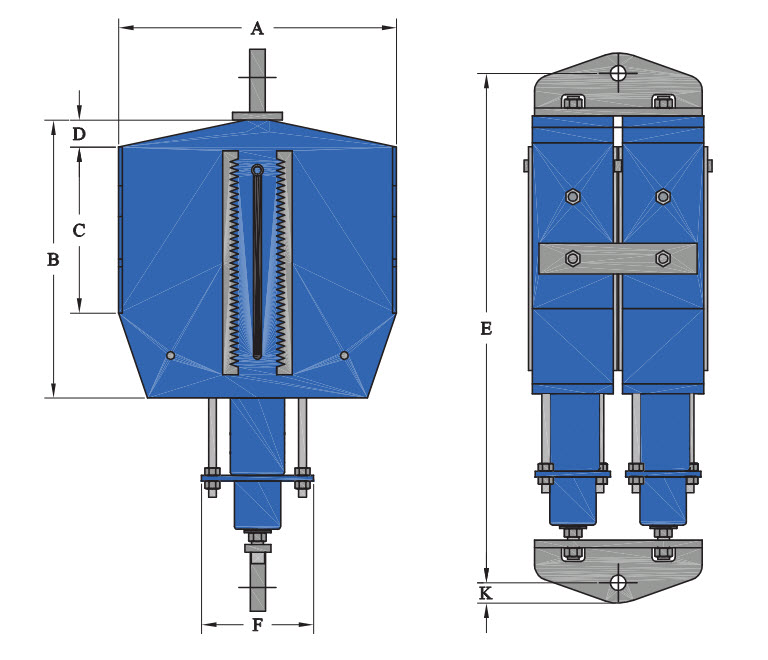

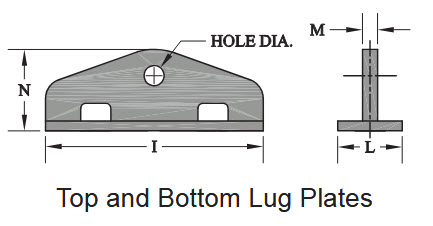

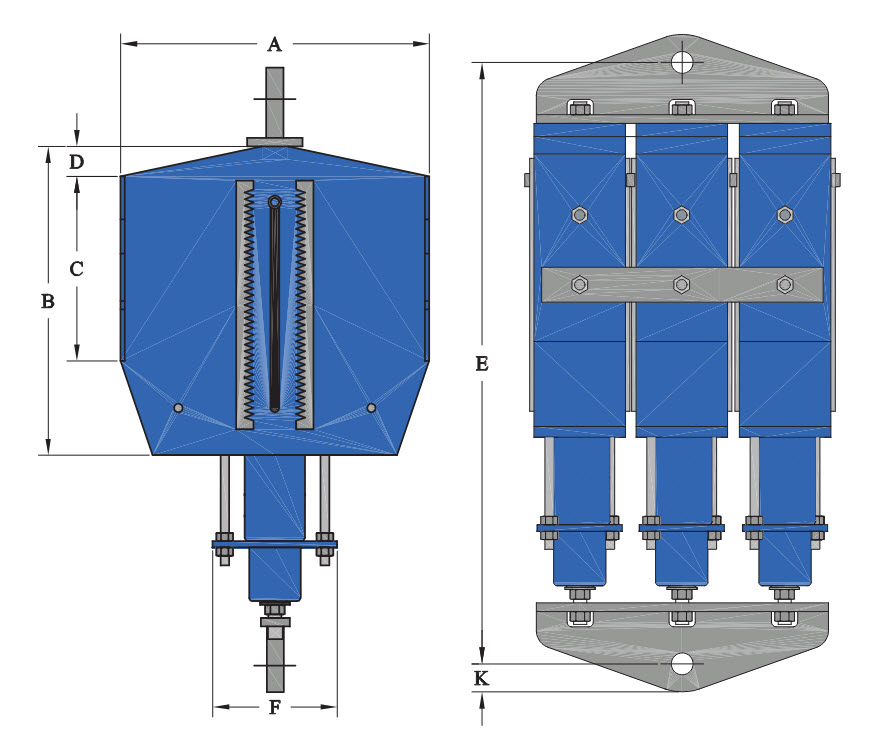

mount feature of the unit allows for the support of the piping system directly above the support node point on the pipe. If required, optional mounting arrangements are available to tie into existing support lugs. Connecting threads are interchangeable with all standard hanger components. RCR units which consist of multiple units tied together for increased load capacity are supplied with a yoke plate at both the top and the bottom connection points.

Springs

Springs are vital to the longevity, safety, and dependable operation of the Rilco Cam Roller™ constants. All springs conform to the rigid requirements of ASTM A229/A229M-99 (2005) Standard Specification for Steel Wire, Oil-Tempered for Mechanical Springs

Performance Range

Rilco Cam Roller™ constants are available with a standard load capacity of 20 lbs (.09 kN) to 120000 lbs (534 kN) with standard travel ranges of 3″ (75mm) through 30″ (450mm). Loads and travels beyond those listed can also be accommodated. Contact the Rilco factory direct for more information.

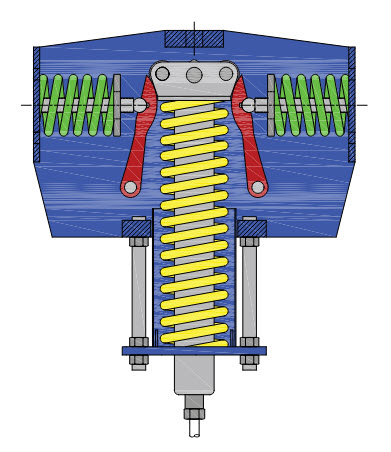

Operational Function

Rilco is proud to announce that the RCR constant support incorporates all of the necessary elements to create a near perfect constant:

- Absolute load setting reliability

- Minimal component friction

- Reliable indicators of travel and load

- Precise adjustment of the unit should deviations be required

The operation of the Rilco Cam Roller™ constant is based in the interaction of force between the main spring load and the forces provided by two interconnected opposing springs. The opposing springs acting in conjunction with the main spring enables achievement of absolute load setting reliability. Loads subjected to the main spring, which is connected through the load column, activates the opposing springs, thus activating a system of specially engineered cams, rollers and pins which in turn also exert force on the main spring. As loads are transported over the travel range of the piping, the forces on the main spring and opposing springs change based upon the angle created by the specific shape of the cams, and the design

characteristics of the spring.

As loading is applied and the travel moves downward towards the apex of the cams, the opposing spring load is minimized in direct proportion to loading on the main spring. Upon reaching the apex, the opposing force is zero, as the main spring is carrying the load without assistance, traversing past the apex, in a downward motion, the direction of the compensating springs begin to reverse thereby reducing the load on the main spring

as well. The constant support is achieved as a result of the alignment of these components so that any deviations in the load are matched exactly with the loading on the main spring.

Loading Adjustments

Due to load deviations or revised process criteria, occasionally adjustments to the Rilco Cam Roller™ constant may become necessary. As a result of our research and engineering attention to detail, Rilco has de-signed into the RCR a feature which ensures precise adjustments. Because the characteristic curves of the interconnected opposing springs and the main spring are exactly alike, only vertical deviation of the loading occurs, therefore an adjustment to the main spring is all that is necessary. The force deviation accomplished by adjusting the main spring pre-tension has the identical effect at each point in the movement cycle thus the ultimate load will remain constant at each adjustment. Travel distances will change proportionally in response to the load revisions.

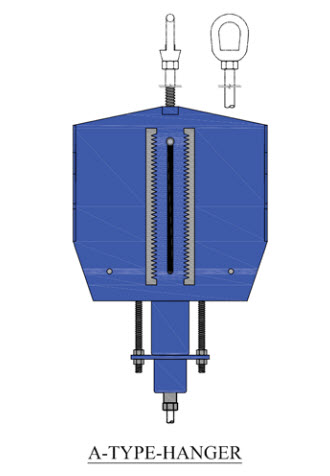

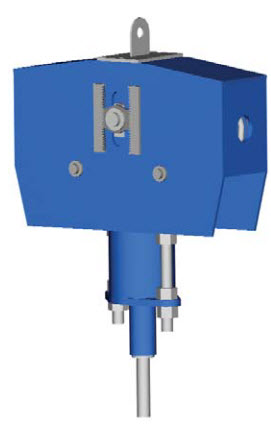

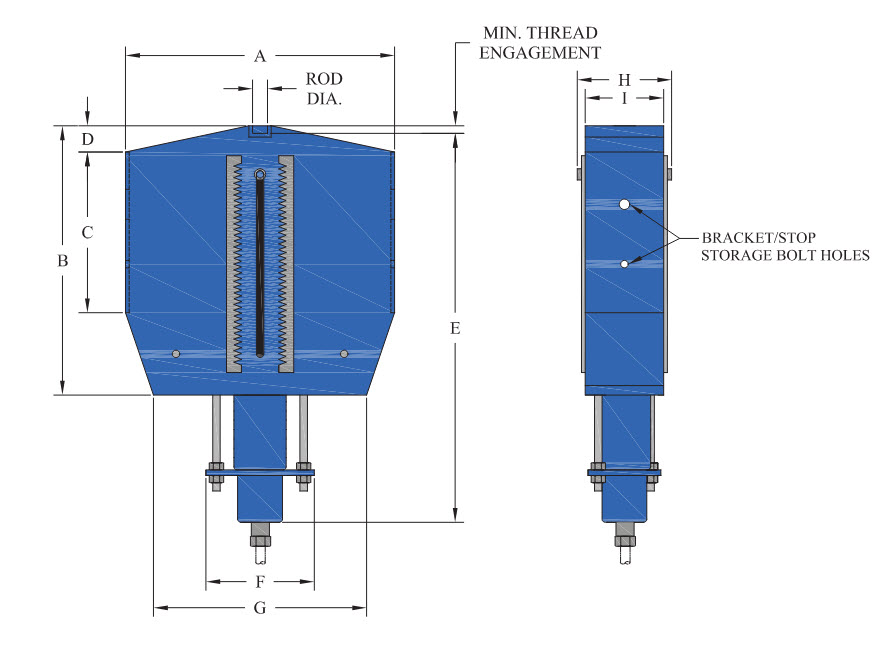

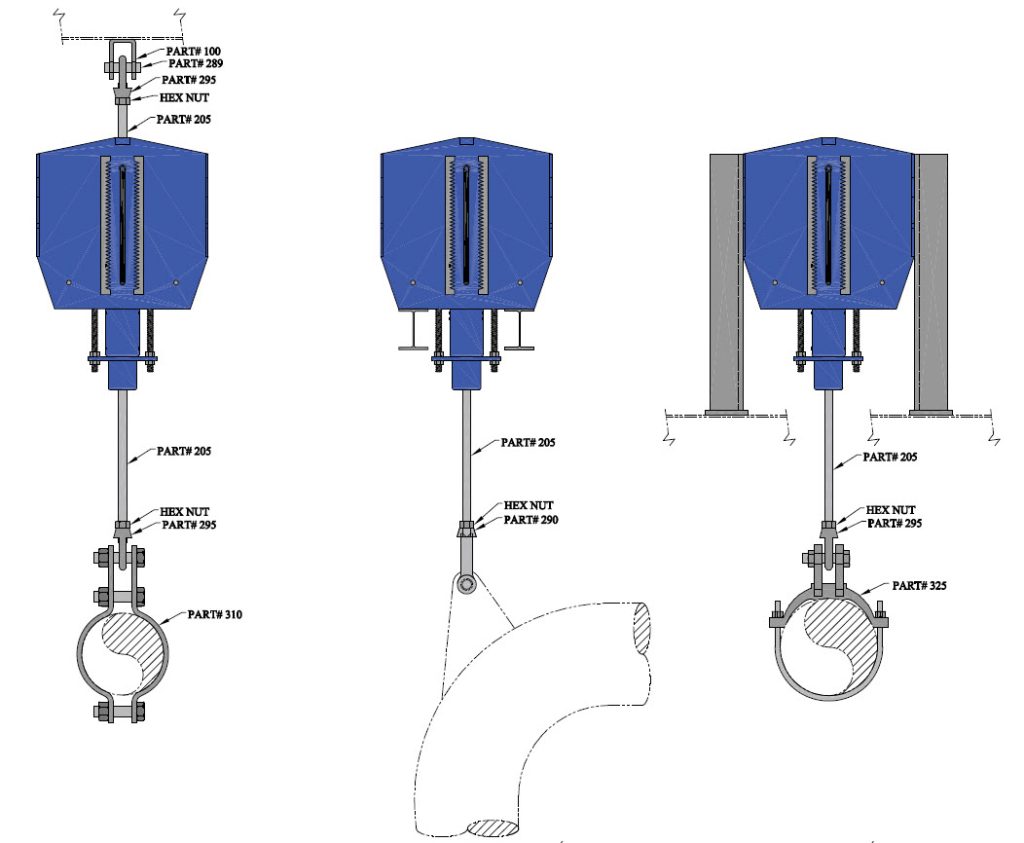

A Type

Type A uses a female thread in the top of the assembly which can receive a fully or partially threaded rod or a bolt. The lower attachment point consists of a turnbuckle with right hand threads for the hanger rod connection.

The thread diameters for both the top and the bottom connections will be driven by the size of constant selected. This design does not require any intermediate attachments, other than the threaded rod, prior to installation.

Type As are available only as single unit assemblies.

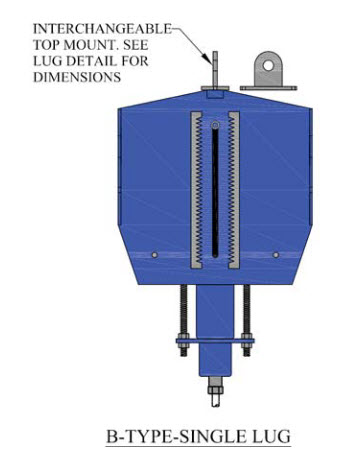

B Type

Type B is defined by a single lug top mount which is bolted to the RCR assembly. This type of arrangement is typically used in situations which require the constant assembly to be close mounted to supporting structure, or in retrofit applications.

The top single lug typically works in conjunction with a clevis or a welded beam attachment. The lower attachment point consists of a turnbuckle with right hand threads for the hanger rod connection for single unit assemblies. Multiple unit assemblies use a single common lug for both the top and bottom connections. They can use the same connection arrangement on the top as the single unit assemblies, but require a clevis or a double lug arrangement for the lower connection.

The hanger rod diameters for both the top and the bottom connections will be driven by the size of constant selected. (single unit assembly shown)

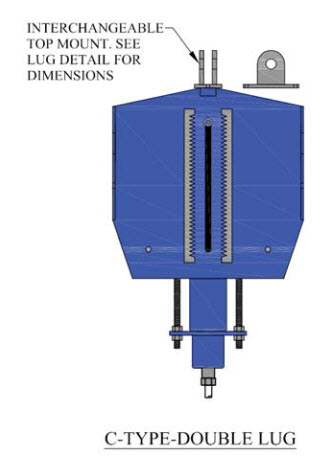

C Type

Type C is defined by a double lug top mount which is bolted to the RCR assembly. This type of arrangement is typically used in situations which require the constant assembly to be close mounted to supporting structure, or in retrofit applications.

The top double lug typically works in conjunction with a structural welding lug or existing attachment plate. The lower attachment point consists of a turnbuckle with right hand threads for the hanger rod connection.

The hanger rod diameters for both the top and the bottom connections will be driven by the size of constant selected. Type Cs are available only as single unit assemblies.

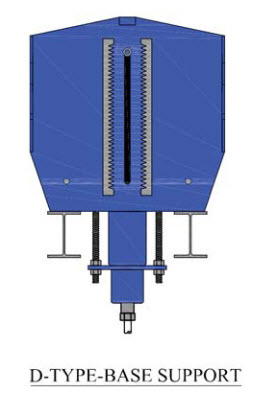

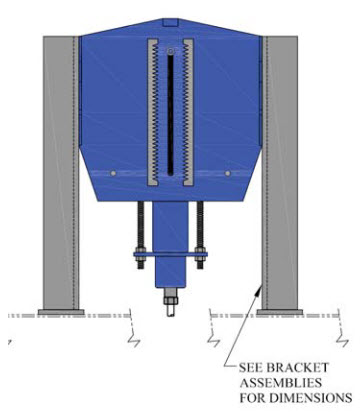

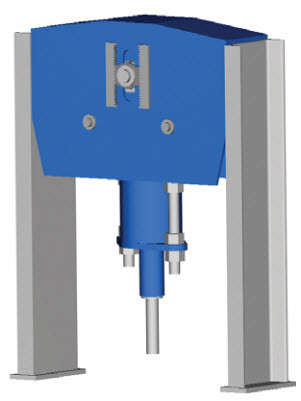

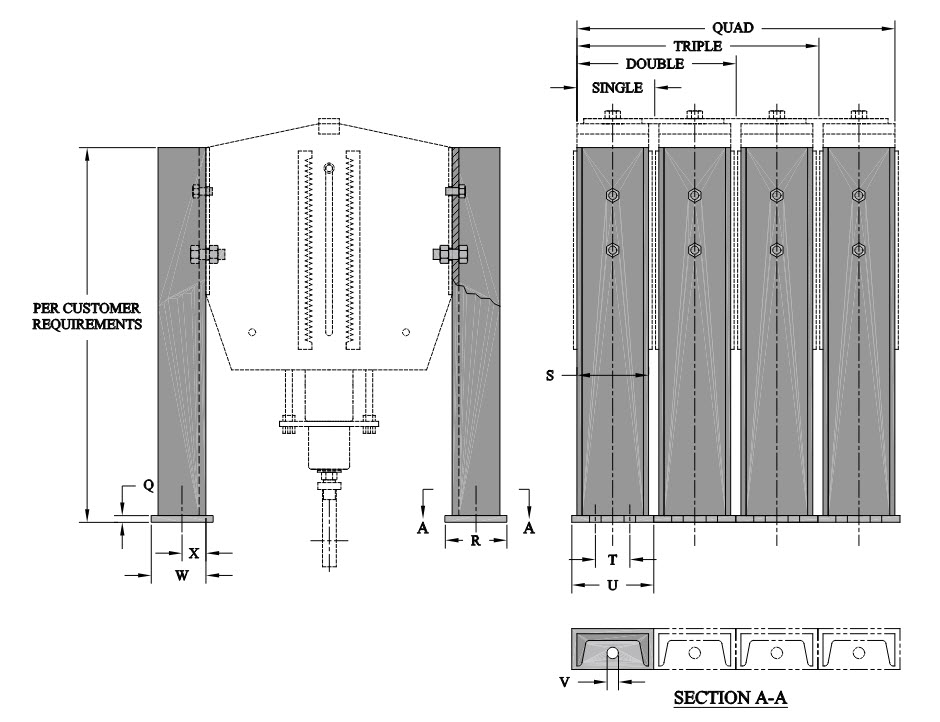

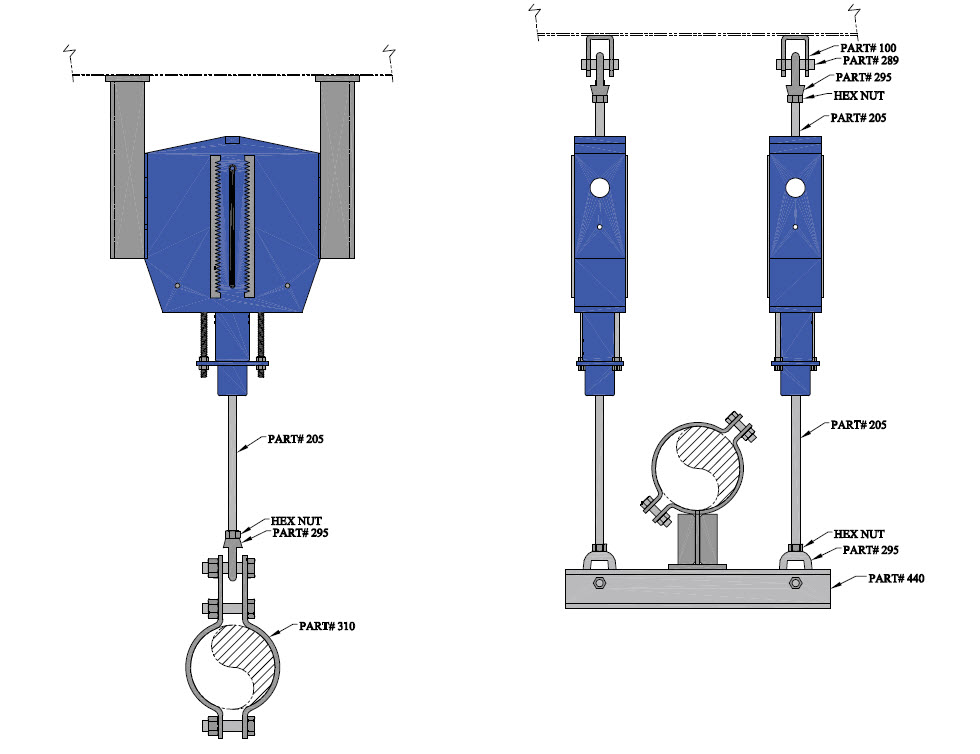

D Type

Type D is a resting type which uses existing structure to directly support the RCR assembly. This arrangement is most often used when little or no space exists below the support structure. This type of constant has no top mount connection, but instead relies on the side brackets for support and transfer of force to the support structure.

The lower attachment point consists of a turnbuckle with right hand threads for the hanger rod connection for single unit assemblies. Multiple unit assemblies use a single common lug for the bottom connection. They require a clevis or a double lug arrangement for the lower connection.

The hanger rod diameter for the bottom connection will be driven by the size of constant selected. (single unit assembly shown)

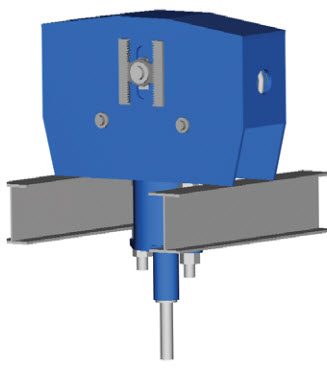

E Type

Type E is a resting type which uses existing

structure to directly support the RCR assembly.

This arrangement is most often used when little or no space exists below the support structure. This type of constant has no top mount connection, but instead relies on existing structure for support.

The lower attachment point consists of a turnbuckle with right hand threads for the hanger rod connection for single unit assemblies. Multiple unit assemblies also utilize the auxiliary side brackets, but use a single common lug for the bottom connection. They require a clevis or a double lug arrangement for the lower connection.

The hanger rod diameter for the bottom connection will be driven by the size of constant selected. (single unit assembly shown)

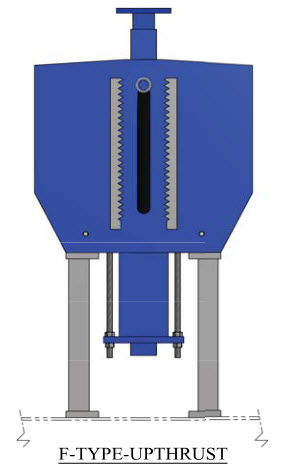

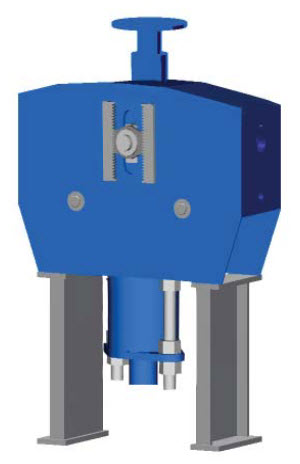

F Type

Type F or upthrust type uses two attached stand-offs to support the RCR assembly with a load column and pad protruding through the top. This arrangement is used when supporting lines or vessels from below. The stand-offs are typically attached to either structural steel or concrete. These offer the same performance and adjustability the other RCR assemblies offer.

Single Unit Constants

See the A, B, C’s of Constant types for top mount arrangements available.

E* refers only to the uppermost blocking position.

Downward travel increases E dimension directly

Min thread Engagement = 1.5x rod diameter.

Use the chart below for dimensions of an RCR

| RCR Identifier | A | B | C | D | E* | F | G | H | I | Rod Dia. | Ext. Unit weight (lbs) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RCR 50-3 | 13.75 | 18 | 10.5 | 1.5 | 20.75 | 6 | 10 | 5.25 | 14.25 | 3/8 UNC | 31 |

| RCR 50-6 | 13.75 | 18 | 10.5 | 1.5 | 20.75 | 6 | 10 | 5.25 | 14.25 | 3/8 UNC | 31 |

| RCR 125-3 | 11.75 | 9.75 | 7.75 | 0 | 13.75 | 6 | 9 | 4.25 | 3.5 | 3/8 UNC | 22 |

| RCR 125-6 | 16.25 | 17.5 | 11 | 1.75 | 21.5 | 6.75 | 10.25 | 5.25 | 4.25 | 3/8 UNC | 42 |

| RCR 175-18 | 18.25 | 31.25 | 17.75 | 1 | 48.25 | 6 | 11.5 | 5.25 | 4.25 | 3/8 UNC | 115 |

| RCR 275-3 | 15.25 | 10.5 | 5.25 | 1 | 14.75 | 5.5 | 11.25 | 5.25 | 4.25 | 3/8 UNC | 33 |

| RCR 275-6 | 16.25 | 17.5 | 10.75 | 0.75 | 25.5 | 5.5 | 11.25 | 5.25 | 4.25 | 3/8 UNC | 55 |

| RCR 225-12 | 17.25 | 25.25 | 12.75 | 1 | 36.75 | 5.5 | 11.25 | 5.25 | 4.25 | 3/8 UNC | 75 |

| RCR 275-12 | 18.25 | 31.25 | 17.75 | 1 | 48.25 | 6 | 11.5 | 5.25 | 4.25 | 3/8 UNC | 115 |

| RCR 325-18 | 20.75 | 32 | 18 | 1 | 47.75 | 7.75 | 14.5 | 6.5 | 5.25 | 3/8 UNC | 165 |

| RCR 400-12 | 19 | 25 | 12.5 | 1.75 | 37.25 | 7.25 | 14.25 | 6.25 | 5.25 | 3/8 UNC | 106 |

| RCR 550-3 | 17.5 | 10.75 | 5.5 | 0.75 | 15.25 | 7 | 13.75 | 6.25 | 5.25 | 3/8 UNC | 46 |

| RCR 550-6 | 18 | 18 | 10.75 | 1.75 | 25.5 | 7.25 | 14.25 | 6.25 | 5.25 | 3/8 UNC | 77 |

| RCR 550-12 | 20.75 | 32 | 18 | 1 | 47.75 | 7.75 | 14.5 | 6.5 | 5.25 | 3/8 UNC | 165 |

| RCR 800-18 | 23.5 | 32.75 | 18.25 | 2 | 49.5 | 7.75 | 14.5 | 6.75 | 5.25 | 1/2 UNC | 223 |

| RCR 900-12 | 20.75 | 25.5 | 14.5 | 2 | 38.25 | 7.5 | 14.25 | 6.75 | 5.25 | 1/2 UNC | 134 |

| RCR 1100-3 | 17.5 | 10.75 | 6.5 | 0.5 | 15.25 | 7.5 | 14.25 | 6.75 | 5.25 | 1/2 UNC | 60 |

| RCR 1100-6 | 19.25 | 18.5 | 10.25 | 2.75 | 26.5 | 7.5 | 14.25 | 6.75 | 5.25 | 1/2 UNC | 95 |

| RCR 1100-12 | 23.5 | 32.75 | 18.25 | 2 | 49.5 | 7.75 | 14.5 | 6.75 | 5.25 | 1/2 UNC | 223 |

| RCR 1200-6 | 19.75 | 12.5 | 10.25 | 1 | 17.5 | 8.75 | 15.75 | 7.25 | 6 | 3/4 UNC | 97 |

| RCR 1650-18 | 26.25 | 33.75 | 21.25 | 2.5 | 54 | 9.5 | 16.5 | 7.5 | 6 | 3/4 UNC | 331 |

| RCR 1800-12 | 24 | 26.5 | 14.5 | 2.25 | 42.25 | 8.75 | 16.25 | 7.25 | 6 | 3/4 UNC | 203 |

| RCR 2200-3 | 19.75 | 12.5 | 10.25 | 1 | 17.5 | 8.75 | 15.75 | 7.25 | 6 | 3/4 UNC | 97 |

| RCR 2200-6 | 22.5 | 19.5 | 9.75 | 4.25 | 26.25 | 8.75 | 16.25 | 7.25 | 6 | 3/4 UNC | 146 |

| RCR 2200-12 | 26.25 | 33.75 | 21.25 | 2.5 | 54 | 9.5 | 16.5 | 7.5 | 6 | 3/4 UNC | 331 |

| RCR 3250-18 | 33.25 | 34.75 | 20.75 | 2.25 | 55.25 | 11.25 | 19.25 | 9 | 7.5 | 1 UNC | 467 |

| RCR 3500-12 | 29.25 | 27.75 | 16.25 | 3 | 43.5 | 11.25 | 19.25 | 9 | 7.5 | 1 UNC | 350 |

| RCR 4300-3 | 23.25 | 13.5 | 8.25 | 1.25 | 18.5 | 10.75 | 19.25 | 9 | 7.5 | 1 UNC | 161 |

| RCR 4300-6 | 28 | 20.25 | 11.25 | 4.25 | 30.25 | 10.75 | 19.25 | 9 | 7.5 | 1 UNC | 253 |

| RCR 4300-12 | 33.25 | 34.75 | 20.75 | 2.25 | 55.25 | 11.25 | 19.25 | 9 | 7.5 | 1 UNC | 467 |

| RCR 5900-18 | 34.75 | 36.5 | 18 | 4.75 | 64.25 | 13.5 | 23.5 | 10.75 | 9 | 1-1/2 UNC | 743 |

| RCR 7100-12 | 33.25 | 29.5 | 14 | 6 | 50.5 | 13.5 | 23.5 | 10.75 | 9 | 1-1/2 UNC | 582 |

| RCR 7500-18 | 45 | 52.25 | 25.5 | 6 | 80 | 13.5 | 23.5 | 11 | 9.25 | 1-1/2 UNC | 1090 |

| RCR 8000-12 | 34.75 | 36.5 | 18 | 4.75 | 64.25 | 13.5 | 23.5 | 10.75 | 9 | 1-1/2 UNC | 743 |

| RCR 8500-3 | 28.5 | 16.5 | 9.5 | 1.5 | 21.75 | 13.25 | 22.75 | 10.75 | 9 | 1-1/2 UNC | 295 |

| RCR 8500-6 | 32 | 22.25 | 11.75 | 6.25 | 35.24 | 13.25 | 22.75 | 10.75 | 9 | 1-1/2 UNC | 403 |

| RCR 8500-12 | 45 | 52.25 | 25.5 | 6 | 80 | 13.5 | 23.5 | 11 | 9.25 | 1-1/2 UNC | 1090 |

| RCR 9000-18 | 45.75 | 38.5 | 26.25 | 2.5 | 67.25 | 15.75 | 26 | 12 | 10 | 1-3/4 UNC | 1213 |

| RCR 10600-12 | 39.25 | 31 | 15.75 | 7.75 | 54 | 15.75 | 25.5 | 11.75 | 10 | 1-3/4 UNC | 833 |

| RCR 11200-18 | 50.25 | 56 | 28 | 8.25 | 84.75 | 15.75 | 26 | 12 | 10 | 1-3/4 UNC | 1520 |

| RCR 12400-18 | 47.25 | 44 | 29.25 | 5 | 82 | 16.5 | 27.25 | 12.5 | 10 | 1-3/4 UNC | 1612 |

| RCR 13000-3 | 30.75 | 18 | 11.25 | 2 | 24 | 15 | 25.5 | 11.75 | 10 | 1-3/4 UNC | 430 |

| RCR 13000-6 | 33.5 | 25 | 11.75 | 5.5 | 37.25 | 15 | 25.5 | 11.75 | 10 | 1-3/4 UNC | 578 |

| RCR 13000-12 | 45.75 | 38.5 | 26.25 | 2.5 | 67.25 | 15.75 | 26 | 12 | 10 | 1-3/4 UNC | 1213 |

| RCR 14400-12 | 43.75 | 36.5 | 15.25 | 12 | 64.75 | 15.75 | 26.5 | 12.5 | 10 | 2 UNC | 1112 |

| RCR 15100-18 | 49.5 | 64 | 33.5 | 9.75 | 101.75 | 16.5 | 27.25 | 12.75 | 10.25 | 2 UNC | 2130 |

| RCR 17300-3 | 32 | 23 | 13 | 2 | 27.75 | 15.25 | 25.5 | 12.5 | 10 | 2 UNC | 580 |

| RCR 17300-6 | 37.25 | 28.25 | 13.5 | 8.5 | 45 | 15.25 | 25.5 | 12.5 | 10 | 2 UNC | 802 |

| RCR 17300-12 | 47.25 | 44 | 29.25 | 5 | 82 | 16.5 | 27.25 | 12.5 | 10 | 2 UNC | 1612 |

| RCR 18100-12 | 48 | 37.75 | 15 | 15 | 68.25 | 18 | 30.25 | 13.75 | 10.75 | 2-1/4 UNC | 1493 |

| RCR 18900-18 | 51.5 | 63.75 | 31.5 | 11.5 | 106.25 | 18 | 30.25 | 14 | 11 | 2-1/4 UNC | 2490 |

| RCR 21500-3 | 34 | 24.75 | 13.75 | 2 | 30 | 17.25 | 29.5 | 13.75 | 10.75 | 2-1/4 UNC | 741 |

| RCR 21500-6 | 43 | 31 | 14 | 9.75 | 46.75 | 17.25 | 29.5 | 13.75 | 10.75 | 2-1/4 UNC | 1047 |

| RCR 21500-12 | 49.5 | 43 | 23 | 9.75 | 84 | 18 | 30.25 | 14 | 11 | 2-1/4 UNC | 1900 |

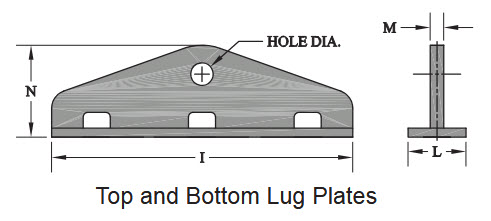

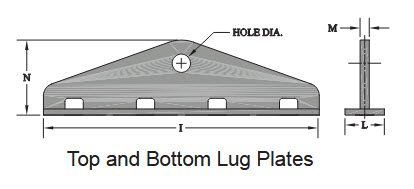

Double Unit Constants

E* refers only to the uppermost blocking position.

Downward travel increases E dimension directly.

Use the chart below for dimensions of an RCR

| RCR Identifier | A | B | C | D | E* | F | H | I | K | L | M | N | Hole Dia. | Rod Dia. | Est. Unit Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RCR 24500-18 | 49 | 44 | 29.25 | 5 | 101.75 | 16.5 | 25.5 | 22.25 | 3.5 | 3.25 | 1.125 | 9.75 | 3.125 | 2-3/4 UNC | 3430 |

| RCR 28500-12 | 45.5 | 36.5 | 15.25 | 122 | 84.5 | 15.75 | 25 | 21.75 | 3.5 | 3.25 | 1.125 | 9.75 | 3.125 | 2-3/4 UNC | 2450 |

| RCR 30000-18 | 51.25 | 64 | 33.5 | 9.75 | 121.5 | 16.5 | 27.25 | 23.75 | 3.5 | 3.5 | 1.375 | 9.75 | 3.125 | 2-3/4 UNC | 4455 |

| RCR 35000-3 | 33.75 | 23 | 13 | 2 | 47.5 | 15.25 | 25 | 21.75 | 3.5 | 3.25 | 1.125 | 9.75 | 3.125 | 2-3/4 UNC | 1355 |

| RCR 35000-6 | 39 | 28.25 | 13.5 | 8.5 | 64.5 | 15.25 | 25 | 21.75 | 3.5 | 3.25 | 1.125 | 9.75 | 3.125 | 2-3/4 UNC | 1805 |

| RCR 35000-12 | 49 | 44 | 29.25 | 5 | 101.75 | 16.5 | 25 | 21.75 | 3.5 | 3.25 | 1.125 | 9.75 | 3.125 | 2-3/4 UNC | 3430 |

| RCR 37000-18 | 53.25 | 63.75 | 31.5 | 11.5 | 128 | 18 | 27.75 | 24.25 | 4.25 | 3.5 | 1.375 | 11.25 | 3.375 | 3 UNC | 5250 |

| RCR 43000-3 | 35.75 | 24.75 | 13.75 | 2 | 51.5 | 17.25 | 27.25 | 23.75 | 4.25 | 3.5 | 1.375 | 11.25 | 3.375 | 3 UNC | 1730 |

| RCR 43000-6 | 45 | 31 | 14 | 9.75 | 68.5 | 17.25 | 27.25 | 23.75 | 4.25 | 3.5 | 1.375 | 11.25 | 3.375 | 3 UNC | 2355 |

| RCR 43000-12 | 51.25 | 43 | 23 | 9.75 | 106.75 | 18 | 27.75 | 24.25 | 4.25 | 3.5 | 1.375 | 11.25 | 3.375 | 3 UNC | 4070 |

Triple Unit Constants

E* refers only to the uppermost blocking position.

Downward travel increases E dimension directly.

Use the chart below for dimensions of an RCR

| RCR Identifier | A | B | C | D | E* | F | H | I | K | L | M | N | Hole Dia. | Rod Dia. | Est. Unit Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RCR 46000-12 | 49 | 44 | 29.25 | 5 | 105.75 | 16.5 | 36.75 | 33.75 | 4.25 | 3.25 | 1.375 | 12.25 | 3.375 | 3-1/4 UNC | 5225 |

| RCR 46000-18 | 51.25 | 64 | 33.5 | 9.75 | 125.5 | 16.5 | 37.5 | 34.25 | 4.25 | 3.25 | 1.375 | 12.25 | 3.375 | 3-1/4 UNC | 6770 |

| RCR 52000-3 | 33.75 | 23 | 13 | 2 | 51.5 | 15.25 | 36.75 | 33.75 | 4.25 | 3.25 | 1.375 | 12.25 | 3.375 | 3-1/4 UNC | 2110 |

| RCR 52000-6 | 39 | 28.25 | 13.5 | 8.5 | 68.5 | 15.25 | 36.75 | 33.75 | 4.25 | 3.25 | 1.375 | 12.25 | 3.375 | 3-1/4 UNC | 2790 |

| RCR 55000-12 | 50.5 | 37.75 | 15 | 15 | 94.25 | 18 | 40.25 | 36.75 | 4.75 | 3.5 | 1.375 | 13.75 | 3.875 | 3-1/2 UNC | 4950 |

| RCR 58000-18 | 53.25 | 63.75 | 31.5 | 11.5 | 132.25 | 18 | 41 | 37.5 | 4.75 | 3.5 | 1.375 | 13.75 | 3.875 | 3-1/2 UNC | 7975 |

| RCR 66000-3 | 35.75 | 24.75 | 13.75 | 2 | 56 | 17.25 | 40.25 | 36.75 | 4.75 | 3.5 | 1.375 | 13.75 | 3.875 | 3-1/2 UNC | 2675 |

| RCR 66000-6 | 45 | 31 | 14 | 9.75 | 72.75 | 17.25 | 40.25 | 36.75 | 4.75 | 3.5 | 1.375 | 13.75 | 3.875 | 3-1/2 UNC | 3610 |

| RCR 66000-12 | 51.25 | 43 | 23 | 9.75 | 111 | 18 | 41 | 37.5 | 4.75 | 3.5 | 1.375 | 13.75 | 3.875 | 3-1/2 UNC | 6190 |

Quadruple Unit Constants

E* refers only to the uppermost blocking position.

Downward travel increases E dimension directly.

Use the chart below for dimensions of an RCR

| RCR Identifier | A | B | C | D | E* | F | H | I | K | L | M | N | Hole Dia. | Rod Dia. | Est. Unit Weight (lbs.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RCR 62000-18 | 51.25 | 64 | 33.5 | 9.75 | 128.5 | 16.5 | 49.25 | 46 | 4.75 | 3.25 | 1.375 | 14.5 | 3.875 | 3-1/2 UNC | 9095 |

| RCR 70000-3 | 33.75 | 23 | 13 | 2 | 54.5 | 15.25 | 48.5 | 45.5 | 4.75 | 3.25 | 1.375 | 14.5 | 3.875 | 3-1/2 UNC | 2870 |

| RCR 70000-6 | 39 | 28.25 | 13.5 | 8.5 | 71.75 | 15.25 | 48.5 | 45.5 | 4.75 | 3.25 | 1.375 | 14.5 | 3.875 | 3-1/2 UNC | 3780 |

| RCR 70000-12 | 50.5 | 37.75 | 15 | 15 | 95.75 | 18 | 53.25 | 49.75 | 5.25 | 3.5 | 1.375 | 15 | 4.375 | 4 UNC | 6710 |

| RCR 74000-18 | 53.25 | 63.75 | 31.5 | 11.5 | 133.75 | 18 | 54.25 | 50.5 | 5.25 | 3.5 | 1.375 | 15 | 4.375 | 4 UNC | 10740 |

| RCR 88000-3 | 35.75 | 24.75 | 13.75 | 2 | 57.5 | 17.25 | 53.25 | 49.75 | 5.25 | 3.5 | 1.375 | 15 | 4.375 | 4 UNC | 3670 |

| RCR 88000-6 | 45 | 31 | 14 | 9.75 | 74.5 | 17.25 | 53.25 | 49.75 | 5.25 | 3.5 | 1.375 | 15 | 4.375 | 4 UNC | 4920 |

| RCR 88000-12 | 51.25 | 43 | 23 | 9.75 | 112.5 | 18 | 54.25 | 50.5 | 5.25 | 3.5 | 1.375 | 15 | 4.375 | 4 UNC | 8360 |

| Single Unit Assembly | Double Unit Assembly | Triple Unit Assembly | Quadruple Unit Assembly | Supporting Channel Size | Q | R | S | U | V | T | W | X |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RCR 50-3 | C3x4.1 | 0.25 | 2.125 | 3 | 3.75 | 0.5 | 0 | 1.75 | 1 | |||

| RCR 50-6 | C3x4.1 | 0.25 | 2.125 | 3 | 3.75 | 0.5 | 0 | 1.75 | 1 | |||

| RCR 125-3 | C3x4.1 | 0.25 | 2.125 | 3 | 3.75 | 0.5 | 0 | 1.75 | 1 | |||

| RCR 125-6 | C3x4.1 | 0.25 | 2.125 | 3 | 3.75 | 0.5 | 0 | 1.75 | 1 | |||

| RCR 175-18 | C4x5.4 | 0.25 | 2.375 | 4 | 4.75 | 0.5 | 2 | 2 | 1 | |||

| RCR 225-12 | C4x5.4 | 0.25 | 2.375 | 4 | 4.75 | 0.5 | 2 | 2 | 1 | |||

| RCR 275-3 | C4x5.4 | 0.25 | 2.375 | 4 | 4.75 | 0.5 | 2 | 2 | 1 | |||

| RCR 275-6 | C4x5.4 | 0.25 | 2.375 | 4 | 4.75 | 0.5 | 2 | 2 | 1 | |||

| RCR 275-12 | C4x5.4 | 0.25 | 2.375 | 4 | 4.75 | 0.5 | 2 | 2 | 1 | |||

| RCR 325-18 | C5x6.7 | 0.25 | 2.5 | 5 | 5.75 | 0.5 | 2.5 | 2.125 | 1 | |||

| RCR 400-12 | C5x6.7 | 0.25 | 2.5 | 5 | 5.75 | 0.5 | 2.5 | 2.125 | 1 | |||

| RCR 550-3 | C5x6.7 | 0.25 | 2.5 | 5 | 5.75 | 0.5 | 2.5 | 2.125 | 1 | |||

| RCR 550-6 | C5x6.7 | 0.25 | 2.5 | 5 | 5.75 | 0.5 | 2.5 | 2.125 | 1 | |||

| RCR 550-12 | C5x6.7 | 0.25 | 2.5 | 5 | 5.75 | 0.5 | 2.5 | 2.125 | 1 | |||

| RCR 800-18 | C5x6.7 | 0.25 | 2.5 | 5 | 5.75 | 0.5 | 2.5 | 2.125 | 1 | |||

| RCR 900-12 | C5x6.7 | 0.25 | 2.5 | 5 | 5.75 | 0.5 | 2.5 | 2.125 | 1 | |||

| RCR 1100-3 | C5x6.7 | 0.25 | 2.5 | 5 | 5.75 | 0.5 | 2.5 | 2.125 | 1 | |||

| RCR 1100-6 | C5x6.7 | 0.25 | 2.5 | 5 | 5.75 | 0.5 | 2.5 | 2.125 | 1 | |||

| RCR 1100-12 | C5x6.7 | 0.25 | 2.5 | 5 | 5.75 | 0.5 | 2.5 | 2.125 | 1 | |||

| RCR 1200-6 | C5x9 | 0.375 | 2.625 | 5 | 5.75 | 0.5 | 2.5 | 2.25 | 1.25 | |||

| RCR 1650-18 | C5x9 | 0.375 | 2.625 | 5 | 5.75 | 0.5 | 2.5 | 2.25 | 1.25 | |||

| RCR 1800-12 | C5x9 | 0.375 | 2.625 | 5 | 5.75 | 0.5 | 2.5 | 2.25 | 1.25 | |||

| RCR 2200-3 | C5x9 | 0.375 | 2.625 | 5 | 5.75 | 0.5 | 2.5 | 2.25 | 1.25 | |||

| RCR 2200-6 | C5x9 | 0.375 | 2.625 | 5 | 5.75 | 0.5 | 2.5 | 2.25 | 1.25 | |||

| RCR 2200-12 | C5x9 | 0.375 | 2.625 | 5 | 5.75 | 0.5 | 2.5 | 2.25 | 1.25 | |||

| RCR 3250-18 | C7x12.25 | 0.5 | 3.25 | 7 | 8 | 0.75 | 2.5 | 2.75 | 1.5 | |||

| RCR 3500-12 | C7x12.25 | 0.5 | 3.25 | 7 | 8 | 0.75 | 2.5 | 2.75 | 1.5 | |||

| RCR 4300-3 | C7x12.25 | 0.5 | 3.25 | 7 | 8 | 0.75 | 2.5 | 2.75 | 1.5 | |||

| RCR 4300-6 | C7x12.25 | 0.5 | 3.25 | 7 | 8 | 0.75 | 2.5 | 2.75 | 1.5 | |||

| RCR 4300-12 | C7x12.25 | 0.5 | 3.25 | 7 | 8 | 0.75 | 2.5 | 2.75 | 1.5 | |||

| RCR 5900-18 | C8x13.75 | 0.5 | 3.375 | 8 | 9 | 0.875 | 2.5 | 2.875 | 1.5 | |||

| RCR 7100-12 | C8x13.75 | 0.5 | 3.375 | 8 | 9 | 0.875 | 2.5 | 2.875 | 1.5 | |||

| RCR 7500-18 | C8x13.75 | 0.5 | 3.375 | 8 | 9 | 0.875 | 2.5 | 2.875 | 1.5 | |||

| RCR 8000-12 | C8x13.75 | 0.5 | 3.375 | 8 | 9 | 0.875 | 2.5 | 2.875 | 1.5 | |||

| RCR 8500-3 | C8x13.75 | 0.5 | 3.375 | 8 | 9 | 0.875 | 2.5 | 2.875 | 1.5 | |||

| RCR 8500-6 | C8x13.75 | 0.5 | 3.375 | 8 | 9 | 0.875 | 2.5 | 2.875 | 1.5 | |||

| RCR 8500-12 | C8x13.75 | 0.5 | 3.375 | 8 | 9 | 0.875 | 2.5 | 2.875 | 1.5 | |||

| RCR 9000-18 | C9x20 | 0.625 | 3.625 | 9 | 10 | 1 | 2.5 | 3.125 | 1.75 | |||

| RCR 10600-12 | C9x20 | 0.625 | 3.625 | 9 | 10 | 1 | 2.5 | 3.125 | 1.75 | |||

| RCR 11200-18 | C9x20 | 0.625 | 3.625 | 9 | 10 | 1 | 2.5 | 3.125 | 1.75 | |||

| RCR 13000-3 | C9x20 | 0.625 | 3.625 | 9 | 10 | 1 | 2.5 | 3.125 | 1.75 | |||

| RCR 13000-6 | C9x20 | 0.625 | 3.625 | 9 | 10 | 1 | 2.5 | 3.125 | 1.75 | |||

| RCR 13000-12 | C9x20 | 0.625 | 3.625 | 9 | 10 | 1 | 2.5 | 3.125 | 1.75 | |||

| RCR 17300-3 | RCR 35000-3 | RCR 52000-3 | RCR 70000-3 | C9x20 | 0.625 | 3.625 | 9 | 10 | 1.25 | 2.5 | 3.125 | 2 |

| RCR 17300-6 | RCR 35000-6 | RCR 52000-6 | RCR 70000-6 | C9x20 | 0.625 | 3.625 | 9 | 10 | 1.25 | 2.5 | 3.125 | 2 |

| RCR 12400-18 | RCR 24500-18 | RCR 46000-12 | RCR 62000-18 | C10x25 | 0.625 | 3.875 | 10 | 11 | 1.25 | 2.5 | 3.375 | 2.125 |

| RCR 14400-12 | RCR 28500-12 | RCR 46000-18 | RCR 70000-12 | C10x25 | 0.625 | 3.875 | 10 | 11 | 1.25 | 2.5 | 3.375 | 2.125 |

| RCR 15100-18 | RCR 30000-18 | RCR 55000-12 | RCR 88000-3 | C10x25 | 0.625 | 3.875 | 10 | 11 | 1.25 | 2.5 | 3.375 | 2.125 |

| RCR 17300-12 | RCR 35000-12 | RCR 66000-3 | RCR 88000-6 | C10x25 | 0.625 | 3.875 | 10 | 11 | 1.25 | 2.5 | 3.375 | 2.125 |

| RCR 18100-12 | RCR 43000-3 | RCR 66000-6 | C10x25 | 0.625 | 3.875 | 10 | 11 | 1.25 | 2.5 | 3.375 | 2.125 | |

| RCR 21500-3 | RCR 43000-6 | C10x25 | 0.625 | 3.875 | 10 | 11 | 1.25 | 2.5 | 3.375 | 2.125 | ||

| RCR 21500-6 | C10x25 | 0.625 | 3.875 | 10 | 11 | 1.25 | 2.5 | 3.375 | 2.125 |

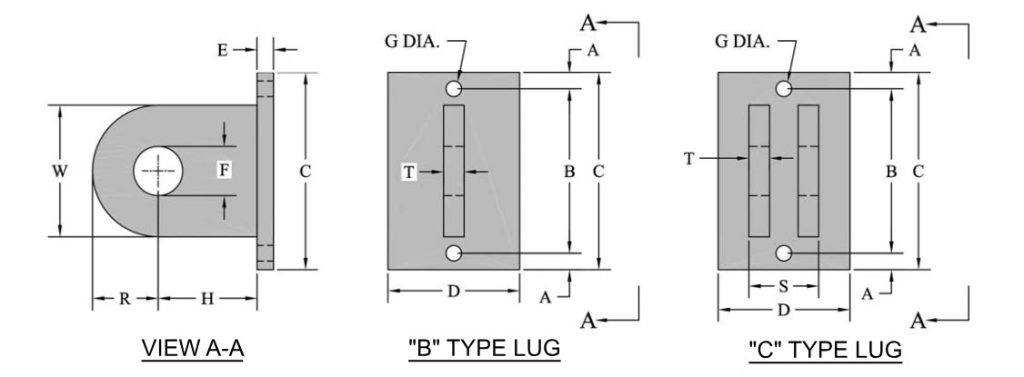

| Size | Hanger Rod Dia. | A | B | C | D | E | F | G Dia. | H | R | S | T | W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RCR 50-3 | 3/8 | 0.625 | 3 | 4.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 1.75 |

| RCR 50-6 | 3/8 | 0.625 | 3 | 4.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 1.75 |

| RCR 125-3 | 3/8 | 0.625 | 3 | 4.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 1.75 |

| RCR 125-6 | 3/8 | 0.625 | 3 | 4.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 1.75 |

| RCR 175-18 | 3/8 | 0.625 | 3 | 4.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 1.75 |

| RCR 225-12 | 3/8 | 0.625 | 3 | 4.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 1.75 |

| RCR 275-3 | 3/8 | 0.625 | 3 | 4.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 1.75 |

| RCR 275-6 | 3/8 | 0.625 | 3 | 4.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 1.75 |

| RCR 275-12 | 3/8 | 0.625 | 3 | 4.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 1.75 |

| RCR 325-18 | 3/8 | 0.8125 | 3.625 | 5.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 2 |

| RCR 400-12 | 3/8 | 0.8125 | 3.625 | 5.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 2 |

| RCR 550-3 | 3/8 | 0.8125 | 3.625 | 5.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 2 |

| RCR 550-6 | 3/8 | 0.8125 | 3.625 | 5.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 2 |

| RCR 550-12 | 3/8 | 0.8125 | 3.625 | 5.25 | 2.25 | 0.375 | 0.625 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 2 |

| RCR 800-18 | 1/2 | 0.6875 | 3.875 | 5.25 | 2.25 | 0.375 | 0.6875 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 2.5 |

| RCR 900-12 | 3/4 | 0.6875 | 3.875 | 5.25 | 2.25 | 0.375 | 0.6875 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 2.5 |

| RCR 1100-3 | 3/4 | 0.6875 | 3.875 | 5.25 | 2.25 | 0.375 | 0.6875 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 2.5 |

| RCR 1100-6 | 3/4 | 0.6875 | 3.875 | 5.25 | 2.25 | 0.375 | 0.6875 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 2.5 |

| RCR 1100-12 | 3/4 | 0.6875 | 3.875 | 5.25 | 2.25 | 0.375 | 0.6875 | 0.5 | 1.5 | 1.25 | 1.25 | 0.25 | 2.5 |

| RCR 1200-6 | 3/4 | 0.875 | 4.25 | 6 | 2.875 | 0.5 | 0.9375 | 0.625 | 1.5 | 1.25 | 1.875 | 0.375 | 2.5 |

| RCR 1650-18 | 3/4 | 0.875 | 4.25 | 6 | 2.875 | 0.5 | 0.9375 | 0.625 | 1.5 | 1.25 | 1.875 | 0.375 | 2.5 |

| RCR 1800-12 | 3/4 | 0.875 | 4.25 | 6 | 2.875 | 0.5 | 0.9375 | 0.625 | 1.5 | 1.25 | 1.875 | 0.375 | 2.5 |

| RCR 2200-3 | 3/4 | 0.875 | 4.25 | 6 | 2.875 | 0.5 | 0.9375 | 0.625 | 1.5 | 1.25 | 1.875 | 0.375 | 2.5 |

| RCR 2200-6 | 3/4 | 0.875 | 4.25 | 6 | 2.875 | 0.5 | 0.9375 | 0.625 | 1.5 | 1.25 | 1.875 | 0.375 | 2.5 |

| RCR 2200-12 | 3/4 | 0.875 | 4.25 | 6 | 2.875 | 0.5 | 0.9375 | 0.625 | 1.5 | 1.25 | 1.875 | 0.375 | 2.5 |

| RCR 4300-3 | 1 | 1.125 | 5.25 | 7.5 | 3.5 | 0.75 | 1.25 | 0.875 | 2 | 1.5 | 1.5 | 0.5 | 3 |

| RCR 4300-6 | 1 | 1.125 | 5.25 | 7.5 | 3.5 | 0.75 | 1.25 | 0.875 | 2 | 1.5 | 2.5 | 0.5 | 3 |

| RCR 3250-18 | 1 | 1.125 | 5.25 | 7.5 | 3.5 | 0.75 | 1.25 | 0.875 | 2 | 1.5 | |||

| RCR 3500-12 | 1 | 1.125 | 5.25 | 7.5 | 3.5 | 0.75 | 1.25 | 0.875 | 2 | 1.5 | |||

| RCR 4300-12 | 1 | 1.125 | 5.25 | 7.5 | 3.5 | 0.75 | 1.25 | 0.875 | 2 | 1.5 | |||

| RCR 5900-18 | 1 -1/2 | 1 | 7 | 9 | 4 | 1 | 1.75 | 1.125 | 3 | 2.5 | |||

| RCR 7100-12 | 1 -1/2 | 1 | 7 | 9 | 4 | 1 | 1.75 | 1.125 | 3 | 2.5 | |||

| RCR 7500-18 | 1 -1/2 | 1.0625 | 7.125 | 9.25 | 4 | 1 | 1.75 | 1.125 | 3 | 2.5 | |||

| RCR 8500-3 | 1 -1/2 | 1 | 7 | 9 | 4 | 1 | 1.75 | 1.125 | 3 | 2.5 | |||

| RCR 8000-12 | 1 -1/2 | 1 | 7 | 9 | 4 | 1 | 1.75 | 1.125 | 3 | 2.5 | |||

| RCR 8500-6 | 1 -1/2 | 1 | 7 | 9 | 4 | 1 | 1.75 | 1.125 | 3 | 2.5 | |||

| RCR 8500-12 | 1 -1/2 | 1.0625 | 7.125 | 9.25 | 4 | 1 | 1.75 | 1.125 | 3 | 2.5 | |||

| RCR 9000-18 | 1 -1/2 | 1.25 | 7.5 | 10 | 4.75 | 1.25 | 2 | 1.375 | 3 | 2.5 | |||

| RCR 10600-12 | 1 -1/2 | 1.25 | 7.5 | 10 | 4.75 | 1.25 | 2 | 1.375 | 3 | 2.5 | |||

| RCR 11200-18 | 1 -1/2 | 1.25 | 7.5 | 10 | 4.75 | 1.25 | 2 | 1.375 | 3 | 2.5 | |||

| RCR 12400-18 | 2 | 1 | 8 | 10 | 4.5 | 1.25 | 2.375 | 1.375 | 4 | 3 | |||

| RCR 13000-3 | 1-3/4 | 1.25 | 7.5 | 10 | 4.75 | 1.25 | 2 | 1.375 | 3 | 2.5 | |||

| RCR 13000-6 | 1-3/4 | 1.25 | 7.5 | 10 | 4.75 | 1.25 | 2 | 1.375 | 3 | 2.5 | |||

| RCR 13000-12 | 1-3/4 | 1.25 | 7.5 | 10 | 4.75 | 1.25 | 2 | 1.375 | 3 | 2.5 | |||

| RCR 14400-12 | 2 | 1 | 8 | 10 | 4.5 | 1.25 | 2.375 | 1.625 | 4 | 3 | |||

| RCR 15100-18 | 2 | 1.0625 | 8.125 | 10.25 | 4.5 | 1.25 | 2.375 | 1.625 | 4 | 3 | |||

| RCR 17300-3 | 2 | 1 | 8 | 10 | 4.5 | 1.25 | 2.375 | 1.625 | 4 | 3 | |||

| RCR 17300-6 | 2 | 1 | 8 | 10 | 4.5 | 1.25 | 2.375 | 1.625 | 4 | 3 | |||

| RCR 17300-12 | 2 | 1 | 8 | 10 | 4.5 | 1.25 | 2.375 | 1.625 | 4 | 3 | |||

| RCR 18100-12 | 2-1/4 | 1.0625 | 8.125 | 10.25 | 4.5 | 1.5 | 2.625 | 1.625 | 4.5 | 3 | |||

| RCR 18900-18 | 2-1/4 | 1.25 | 8.5 | 11 | 4.5 | 1.5 | 2.625 | 1.625 | 4.5 | 3 | |||

| RCR 21500-3 | 2-1/4 | 1.0625 | 8.125 | 10.25 | 4.5 | 1.5 | 2.625 | 1.625 | 4.5 | 3 | |||

| RCR 21500-6 | 2-1/4 | 1.0625 | 8.125 | 10.25 | 4.5 | 1.5 | 2.625 | 1.625 | 4.5 | 3 | |||

| RCR 21500-12 | 2-1/4 | 1.25 | 8.125 | 11 | 4.5 | 1.5 | 2.625 | 1.625 | 4.5 | 3 | |||

Notes:

- For loads which fall between those shown, select the next highest.

- For travel which fall between those shown, select the next highest.

| Load (lb) | 3" of Travel | 6" of Travel | 12" of Travel | 18" of Travel |

|---|---|---|---|---|

| 25 | RCR 50-3 (3/8) | RCR 50-6 (3/8) | ||

| 38 | RCR 50-3 (3/8) | RCR 50-6 (3/8) | ||

| 50 | RCR 50-3 (3/8) | RCR 50-6 (3/8) | ||

| 75 | RCR 125-3 (3/8) | RCR 125-6 (3/8) | ||

| 100 | RCR 125-3 (3/8) | RCR 125-6 (3/8) | RCR 225-12 (3/8) | |

| 125 | RCR 125-3 (3/8) | RCR 125-6 (3/8) | RCR 225-12 (3/8) | RCR 175-18 (3/8) |

| 175 | RCR 275-3 (3/8) | RCR 275-6 (3/8) | RCR 225-12 (3/8) | RCR 175-18 (3/8) |

| 225 | RCR 275-3 (3/8) | RCR 275-6 (3/8) | RCR 225-12 (3/8) | RCR 325-18 (3/8) |

| 275 | RCR 275-3 (3/8) | RCR 275-6 (3/8) | RCR 275-12 (3/8) | RCR 325-18 (3/8) |

| 325 | RCR 550-3 (3/8) | RCR 550-6 (3/8) | RCR 400-12 (3/8) | RCR 325-18 (3/8) |

| 400 | RCR 550-3 (3/8) | RCR 550-6 (3/8) | RCR 400-12 (3/8) | RCR 800-18 (1/2) |

| 475 | RCR 550-3 (3/8) | RCR 550-6 (3/8) | RCR 550-12 (3/8) | RCR 800-18 (1/2) |

| 550 | RCR 550-3 (3/8) | RCR 550-6 (3/8) | RCR 550-12 (3/8) | RCR 800-18 (1/2) |

| 625 | RCR 1100-3 (1/2) | RCR 1100-6 (1/2) | RCR 900-12 (1/2) | RCR 800-18 (1/2) |

| 700 | RCR 1100-3 (1/2) | RCR 1100-6 (1/2) | RCR 900-12 (1/2) | RCR 800-18 (1/2) |

| 800 | RCR 1100-3 (1/2) | RCR 1100-6 (1/2) | RCR 900-12 (1/2) | RCR 800-18 (1/2) |

| 900 | RCR 1100-3 (1/2) | RCR 1100-6 (1/2) | RCR 900-12 (1/2) | RCR 1650-18 (3/4) |

| 1000 | RCR 1100-3 (1/2) | RCR 1100-6 (1/2) | RCR 1100-12 (1/2) | RCR 1650-18 (3/4) |

| 1100 | RCR 1100-3 (1/2) | RCR 1100-6 (1/2) | RCR 1100-12 (1/2) | RCR 1650-18 (3/4) |

| 1200 | RCR 2200-3 (3/4) | RCR 1200-6 (3/4) | RCR 1800-12 (3/4) | RCR 1650-18 (3/4) |

| 1350 | RCR 2200-3 (3/4) | RCR 2200-6 (3/4) | RCR 1800-12 (3/4) | RCR 1650-18 (3/4) |

| 1500 | RCR 2200-3 (3/4) | RCR 2200-6 (3/4) | RCR 1800-12 (3/4) | RCR 1650-18 (3/4) |

| 1650 | RCR 2200-3 (3/4) | RCR 2200-6 (3/4) | RCR 1800-12 (3/4) | RCR 1650-18 (3/4) |

| 1800 | RCR 2200-3 (3/4) | RCR 2200-6 (3/4) | RCR 1800-12 (3/4) | RCR 3250-18 (1) |

| 2000 | RCR 2200-3 (3/4) | RCR 2200-6 (3/4) | RCR 2200-12 (3/4) | RCR 3250-18 (1) |

| 2200 | RCR 2200-3 (3/4) | RCR 2200-6 (3/4) | RCR 2200-12 (3/4) | RCR 3250-18 (1) |

| 2400 | RCR 4300-3 (1) | RCR 4300-6 (1) | RCR 3500-12 (1) | RCR 3250-18 (1) |

| 2600 | RCR 4300-3 (1) | RCR 4300-6 (1) | RCR 3500-12 (1) | RCR 3250-18 (1) |

| 2800 | RCR 4300-3 (1) | RCR 4300-6 (1) | RCR 3500-12 (1) | RCR 3250-18 (1) |

| 3000 | RCR 4300-3 (1) | RCR 4300-6 (1) | RCR 3500-12 (1) | RCR 3250-18 (1) |

| 3250 | RCR 4300-3 (1) | RCR 4300-6 (1) | RCR 3500-12 (1) | RCR 3250-18 (1) |

| 3500 | RCR 4300-3 (1) | RCR 4300-6 (1) | RCR 3500-12 (1) | RCR 5900-18 (1-1/2) |

| 3750 | RCR 4300-3 (1) | RCR 4300-6 (1) | RCR 4300-12 (1) | RCR 5900-18 (1-1/2) |

| 4000 | RCR 4300-3 (1) | RCR 4300-6 (1) | RCR 4300-12 (1) | RCR 5900-18 (1-1/2) |

| 4300 | RCR 4300-3 (1) | RCR 4300-6 (1) | RCR 4300-12 (1) | RCR 5900-18 (1-1/2) |

| 4600 | RCR 8500-3 (1-1/2) | RCR 8500-6 (1-1/2) | RCR 7100-12 (1-1/2) | RCR 5900-18 (1-1/2) |

| 4900 | RCR 8500-3 (1-1/2) | RCR 8500-6 (1-1/2) | RCR 7100-12 (1-1/2) | RCR 5900-18 (1-1/2) |

| 5200 | RCR 8500-3 (1-1/2) | RCR 8500-6 (1-1/2) | RCR 7100-12 (1-1/2) | RCR 5900-18 (1-1/2) |

| 5500 | RCR 8500-3 (1-1/2) | RCR 8500-6 (1-1/2) | RCR 7100-12 (1-1/2) | RCR 5900-18 (1-1/2) |

| 5900 | RCR 8500-3 (1-1/2) | RCR 8500-6 (1-1/2) | RCR 7100-12 (1-1/2) | RCR 5900-18 (1-1/2) |

| 6300 | RCR 8500-3 (1-1/2) | RCR 8500-6 (1-1/2) | RCR 7100-12 (1-1/2) | RCR 7500-18 (1-1/2) |

| 6700 | RCR 8500-3 (1-1/2) | RCR 8500-6 (1-1/2) | RCR 7100-12 (1-1/2) | RCR 7500-18 (1-1/2) |

| 7100 | RCR 8500-3 (1-1/2) | RCR 8500-6 (1-1/2) | RCR 7100-12 (1-1/2) | RCR 7500-18 (1-1/2) |

| 7500 | RCR 8500-3 (1-1/2) | RCR 8500-6 (1-1/2) | RCR 8000-12 (1-1/2) | RCR 7500-18 (1-1/2) |

| 8000 | RCR 8500-3 (1-1/2) | RCR 8500-6 (1-1/2) | RCR 8000-12 (1-1/2) | RCR 9000-18 (1-3/4) |

| 8500 | RCR 8500-3 (1-1/2) | RCR 8500-6 (1-1/2) | RCR 8500-12 (1-1/2) | RCR 9000-18 (1-3/4) |

| 9000 | RCR 13000-3 (1-3/4) | RCR 13000-6 (1-3/4) | RCR 10600-12 (1-3/4) | RCR 9000-18 (1-3/4) |

| 9500 | RCR 13000-3 (1-3/4) | RCR 13000-6 (1-3/4) | RCR 10600-12 (1-3/4) | RCR 12000-18 (1-3/4) |

| 10000 | RCR 13000-3 (1-3/4) | RCR 13000-6 (1-3/4) | RCR 10600-12 (1-3/4) | RCR 12000-18 (1-3/4) |

| 10600 | RCR 13000-3 (1-3/4) | RCR 13000-6 (1-3/4) | RCR 10600-12 (1-3/4) | RCR 12000-18 (1-3/4) |

| 11200 | RCR 13000-3 (1-3/4) | RCR 13000-6 (1-3/4) | RCR 13000-12 (1-3/4) | RCR 12000-18 (1-3/4) |

| 11800 | RCR 13000-3 (1-3/4) | RCR 13000-6 (1-3/4) | RCR 13000-12 (1-3/4) | RCR 12400-18 (2) |

| 12400 | RCR 13000-3 (1-3/4) | RCR 13000-6 (1-3/4) | RCR 13000-12 (1-3/4) | RCR 12400-18 (2) |

| 13000 | RCR 13000-3 (1-3/4) | RCR 13000-6 (1-3/4) | RCR 13000-12 (1-3/4) | RCR 15100-18 (2) |

| 13700 | RCR 17300-3 (2) | RCR 17300-6 (2) | RCR 14400-12 (2) | RCR 15100-18 (2) |

| 14400 | RCR 17300-3 (2) | RCR 17300-6 (2) | RCR 14400-12 (2) | RCR 15100-18 (2) |

| 15100 | RCR 17300-3 (2) | RCR 17300-6 (2) | RCR 17300-12 (2) | RCR 15100-18 (2) |

| 15800 | RCR 17300-3 (2) | RCR 17300-6 (2) | RCR 17300-12 (2) | RCR 18900-18 (2-1/4) |

| 16500 | RCR 17300-3 (2) | RCR 17300-6 (2) | RCR 17300-12 (2) | RCR 18900-18 (2-1/4) |

| 17300 | RCR 17300-3 (2) | RCR 17300-6 (2) | RCR 17300-12 (2) | RCR 18900-18 (2-1/4) |

| 18100 | RCR 21500-3 (2-1/4) | RCR 21500-6 (2-1/4) | RCR 18100-12 (2-1/4) | RCR 18900-18 (2-1/4) |

| 18900 | RCR 21500-3 (2-1/4) | RCR 21500-6 (2-1/4) | RCR 21500-12 (2-1/4) | RCR 18900-18 (2-1/4) |

| 19700 | RCR 21500-3 (2-1/4) | RCR 21500-6 (2-1/4) | RCR 21500-12 (2-1/4) | RCR 24500-18 (2-3/4) |

| 20500 | RCR 21500-3 (2-1/4) | RCR 21500-6 (2-1/4) | RCR 21500-12 (2-1/4) | RCR 24500-18 (2-3/4) |

| 21500 | RCR 21500-3 (2-1/4) | RCR 21500-6 (2-1/4) | RCR 21500-12 (2-1/4) | RCR 24500-18 (2-3/4) |

| 22500 | RCR 35000-3 (2-3/4) | RCR 35000-6 (2-3/4) | RCR 28500-12 (2-3/4) | RCR 24500-18 (2-3/4) |

| 23500 | RCR 35000-3 (2-3/4) | RCR 35000-6 (2-3/4) | RCR 28500-12 (2-3/4) | RCR 24500-18 (2-3/4) |

| 24500 | RCR 35000-3 (2-3/4) | RCR 35000-6 (2-3/4) | RCR 28500-12 (2-3/4) | RCR 24500-18 (2-3/4) |

| 25500 | RCR 35000-3 (2-3/4) | RCR 35000-6 (2-3/4) | RCR 28500-12 (2-3/4) | RCR 30000-18 (2-3/4) |

| 27000 | RCR 35000-3 (2-3/4) | RCR 35000-6 (2-3/4) | RCR 28500-12 (2-3/4) | RCR 30000-18 (2-3/4) |

| 28500 | RCR 35000-3 (2-3/4) | RCR 35000-6 (2-3/4) | RCR 28500-12 (2-3/4) | RCR 30000-18 (2-3/4) |

| 30000 | RCR 35000-3 (2-3/4) | RCR 35000-6 (2-3/4) | RCR 35000-12 (2-3/4) | RCR 30000-18 (2-3/4) |

| 31500 | RCR 35000-3 (2-3/4) | RCR 35000-6 (2-3/4) | RCR 35000-12 (2-3/4) | RCR 37000-18 (3) |

| 33000 | RCR 35000-3 (2-3/4) | RCR 35000-6 (2-3/4) | RCR 35000-12 (2-3/4) | RCR 37000-18 (3) |

| 35000 | RCR 35000-3 (2-3/4) | RCR 35000-6 (2-3/4) | RCR 35000-12 (2-3/4) | RCR 37000-18 (3) |

| 37000 | RCR 43000-3 (3) | RCR 43000-6 (3) | RCR 43000-12 (3) | RCR 37000-18 (3) |

| 39000 | RCR 43000-3 (3) | RCR 43000-6 (3) | RCR 43000-12 (3) | RCR 46000-18 (3-1/4) |

| 41000 | RCR 43000-3 (3) | RCR 43000-6 (3) | RCR 43000-12 (3) | RCR 46000-18 (3-1/4) |

| 43000 | RCR 43000-3 (3) | RCR 43000-6 (3) | RCR 43000-12 (3) | RCR 46000-18 (3-1/4) |

| 46000 | RCR 52000-3 (3-1/4) | RCR 52000-6 (3-1/4) | RCR 46000-12 (3-1/4) | RCR 46000-18 (3-1/4) |

| 49000 | RCR 52000-3 (3-1/4) | RCR 52000-6 (3-1/4) | RCR 55000-12 (3-1/2) | RCR 58000-18 (3-1/2) |

| 52000 | RCR 52000-3 (3-1/4) | RCR 52000-6 (3-1/4) | RCR 55000-12 (3-1/2) | RCR 58000-18 (3-1/2) |

| 55000 | RCR 66000-3 (3-1/2) | RCR 66000-6 (3-1/2) | RCR 55000-12 (3-1/2) | RCR 58000-18 (3-1/2) |

| 58000 | RCR 66000-3 (3-1/2) | RCR 66000-6 (3-1/2) | RCR 66000-12 (3-1/2) | RCR 58000-18 (3-1/2) |

| 62000 | RCR 66000-3 (3-1/2) | RCR 66000-6 (3-1/2) | RCR 66000-12 (3-1/2) | RCR 62000-18 (3-1/2) |

| 66000 | RCR 66000-3 (3-1/2) | RCR 66000-6 (3-1/2) | RCR 66000-12 (3-1/2) | RCR 74000-18 (4) |

| 70000 | RCR 70000-3 (3-1/2) | RCR 70000-6 (3-1/2) | RCR 70000-12 (4) | RCR 74000-18 (4) |

| 74000 | RCR 88000-3 (4) | RCR 88000-6 (4) | RCR 88000-12 (4) | RCR 74000-18 (4) |

| 78000 | RCR 88000-3 (4) | RCR 88000-6 (4) | RCR 88000-12 (4) | |

| 83000 | RCR 88000-3 (4) | RCR 88000-6 (4) | RCR 88000-12 (4) | |

| 88000 | RCR 88000-3 (4) | RCR 88000-6 (4) | RCR 88000-12 (4) |