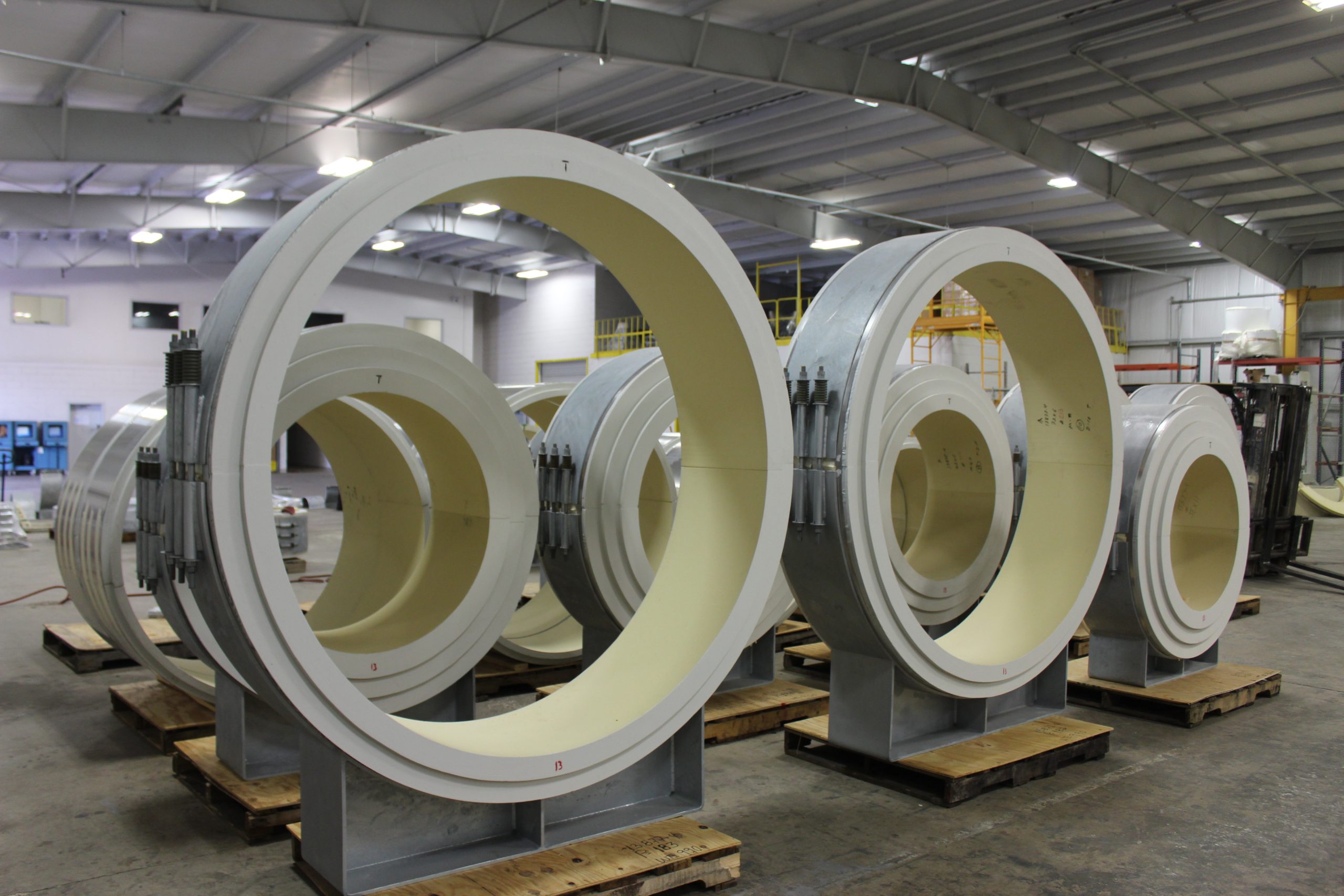

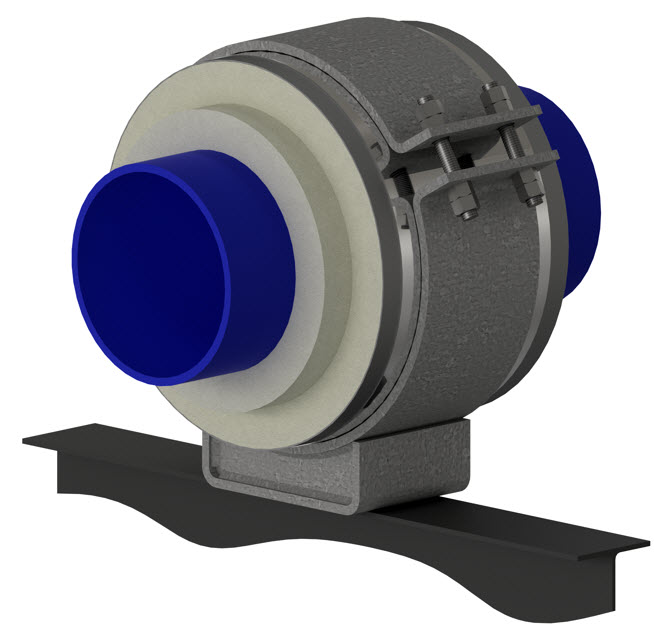

Polyurethane Supports (Cold)

Rilco is among the companies that pioneered modern, industry standard polyurethane pipe supports. These supports are disigned with the latest technology and the highest quality materials. The insulation can be molded to the thickness and layering of process line insulation to ensure proper field fit per ASTM C585. Condensation is eliminated along with any associated field corrosion. Additionally, the design eliminates any temperature fluctuation at support points of process fluid. These designs are customizable to meet a variety of requirements. Please contact us for more details.

Temperature, Thickness and Pipe Size Range

- Temperature Range: -425° F to 275° F

- Insulation Thickness Range: 0.5 in. to 10 in.

- Pipe Size Range: 0.5 in. to 120 in.

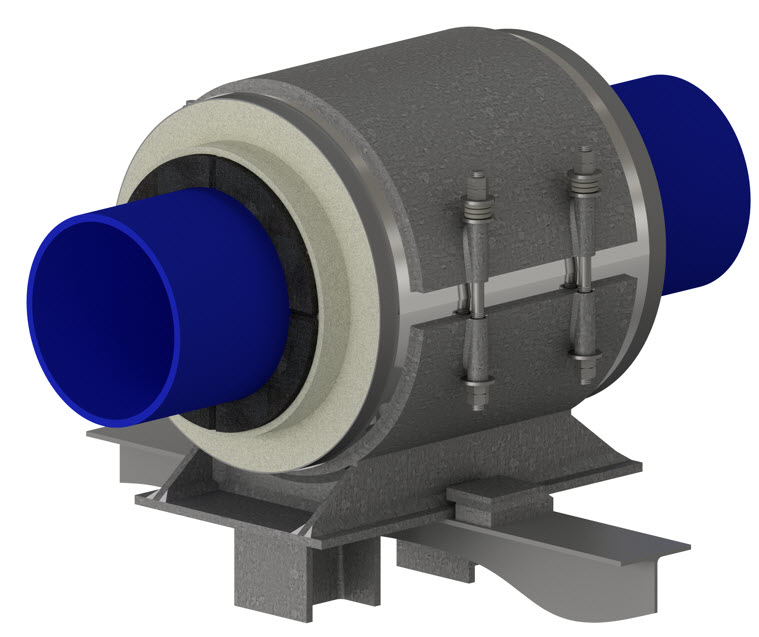

Sleeve Design

The Rilco sleeve design is the modern approach to supporting piping which will soon become standard that all other pre-insulated supports are judged by. The sleeve design is referred to as such due to the unique use of steel tubes (sleeves) attached to both the upper and lower support components. The use of the Belleville washers included with the fasteners are the key to the effectiveness of the support design and require the “float” of the fastener within the upper sleeve to manage the expansion and/or contraction while maintaining proper clamping force on the pipe to prevent displacement between the process pipe and the pipe support. Rilco has performed manual calculations, FEA and thermal analysis, and physical testing on these style supports to have the confidence to say that Rilco can design supports that meet your loading, movement and heat loss requirements.

This Rilco standard design includes steel sleeves and Belleville washers. The washers, included in this sleeve design, are engineered to maintain a constant clamping force throughout the pipeline temperature range to accommodate the expansion and contraction of the process pipe.

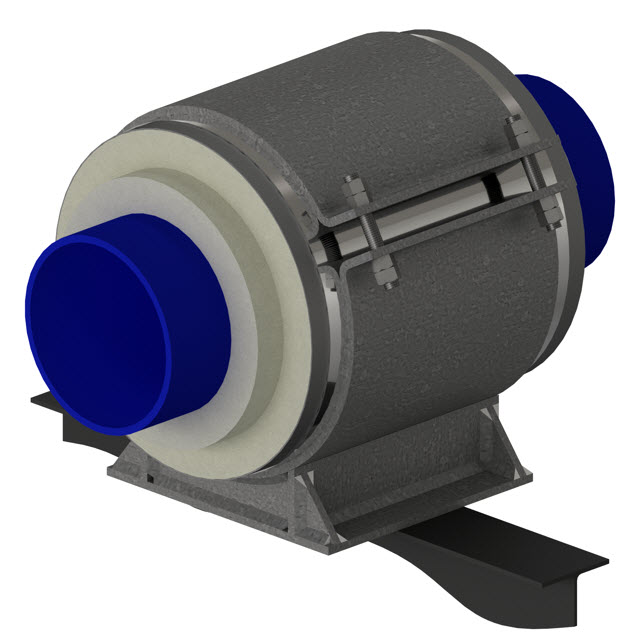

Bent-Ear Design

The Rilco traditional design of bent ear which is the standard which is currently the accepted standard for the pre-insulated pipe support. This design relies on the elasticity of the formed ear section of the cradle to maintain the clamping force throughout the pipeline temperature range.

Sliding

Product Details (Model # CS-1000)

Additional Models

Application & Features

- Accommodates axial travel up to 3” if shoe is offset from supporting steel

- Temperature range: from -425° F to 275° F

- Higher temperature applications available

- Teflon®/2B SS304 slide plates on shoe and supporting steel

- Design loads based on a safety factor of 5

- A36 Steel construction

- See technical specification RHS-750

- Test results available upon request

- Steel finish available in galvanized or painted finishes

- Support features high density water blown polyurethane with vapor barrier

- Support constructed in accordance with ASME B31.1, B31.3 and MSS-SP58

- Exposed surfaces of polyurethane are coated with monolar mastic

- Support supplied with structural lateral restraint

- A307 or A193 B7 Plated bolts/studs

Required data when ordering

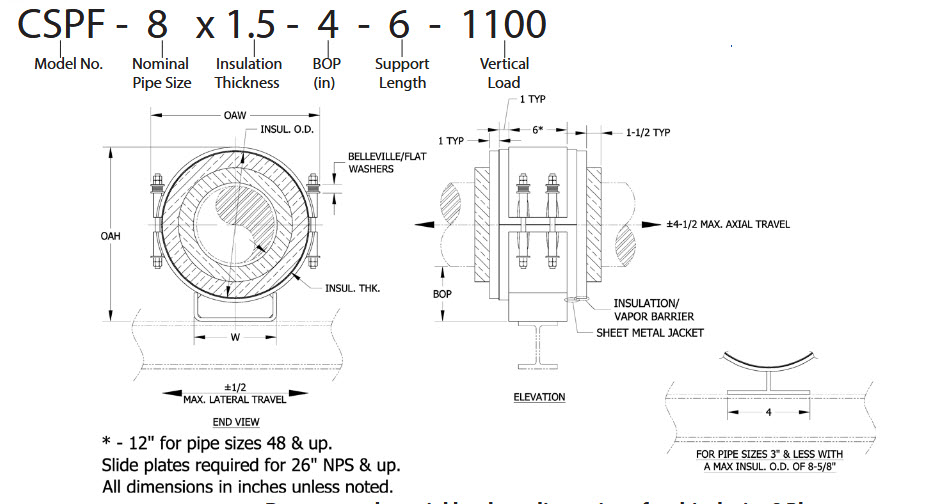

- Part Number

- Nominal Pipe Size

- Insulation Thickness

- Vertical Load

- Lateral & Axial Movements

- Operating Temperature

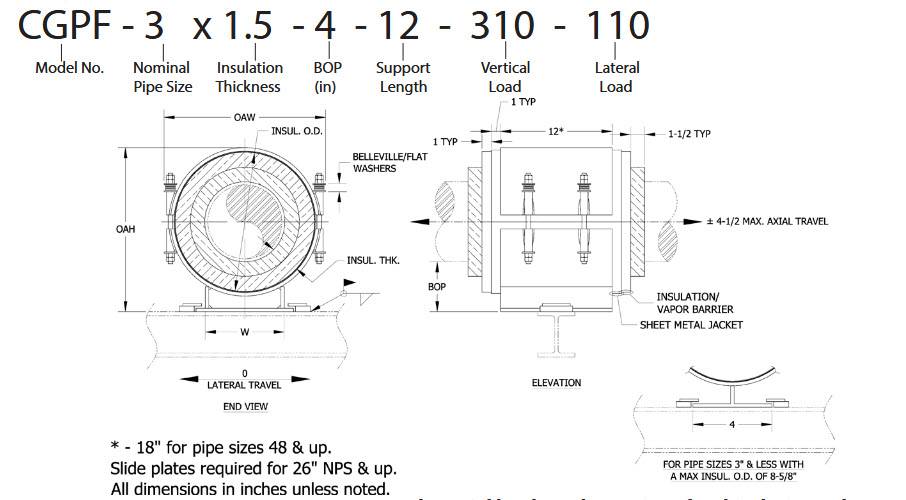

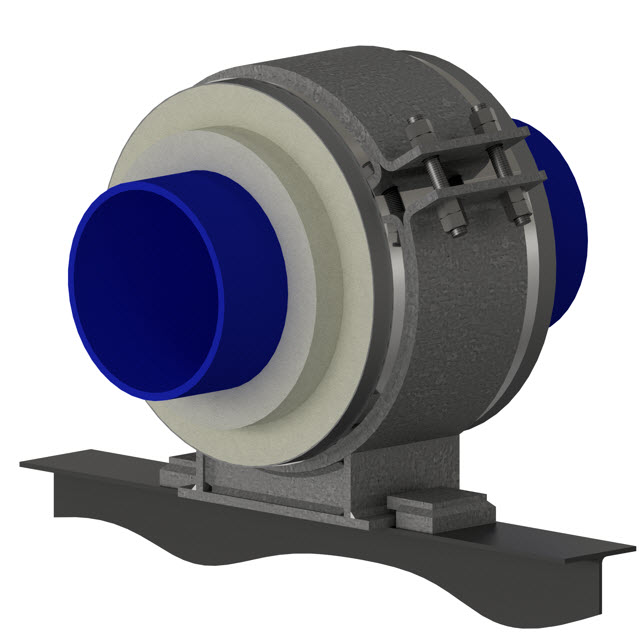

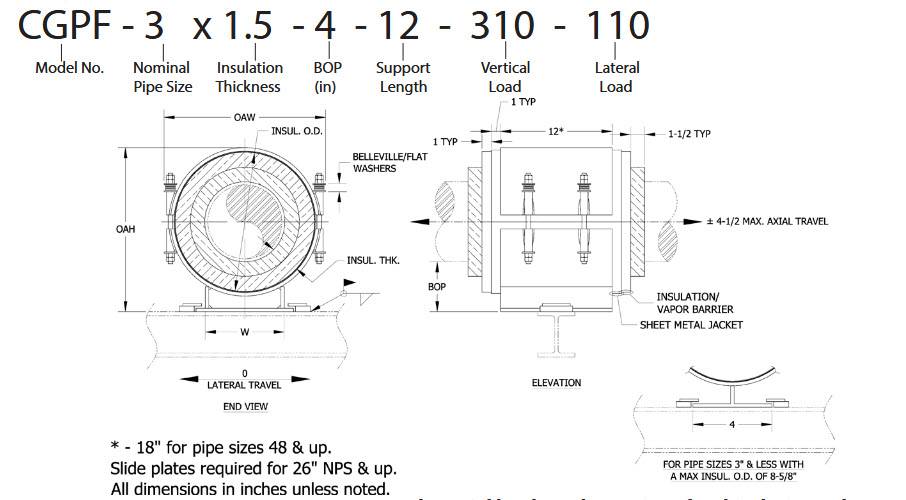

Guided

Product Details (Model # CG-3000)

Additional Models

Application & Features

- Accommodates axial travel up to 3” if shoe is offset from supporting steel

- Accommodates lateral load up to 50% of actual vertical load

- Temperature range: from -425° F to 275° F

- Higher temperature applications available

- Teflon®/2B SS304 slide plates on shoe and supporting steel

- Design loads based on a safety factor of 5

- A36 Steel construction

- See technical specification RHS-750

- Test results available upon request

- Steel finish available in galvanized or painted finishes

- Support features high density water blown polyurethane with vapor barrier

- Support constructed in accordance with ASME B31.1, B31.3 and MSS-SP58

- Exposed surfaces of polyurethane are coated with monolar mastic

- Support supplied with structural lateral restraint

- A307 or A193 B7 Plated bolts/studs

Required data when ordering

- Part Number

- Pipe Size

- Insulation Thickness

- Vertical Load

- Lateral & Axial Movements

- Operating Temperature

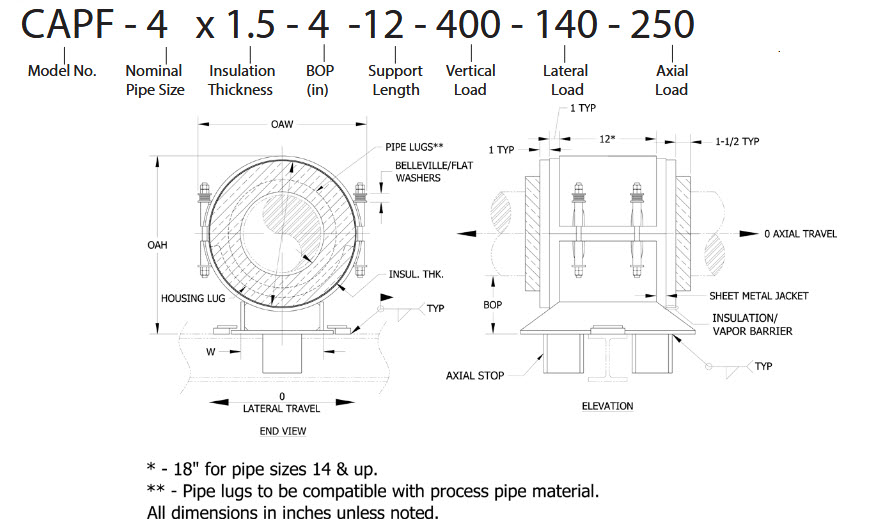

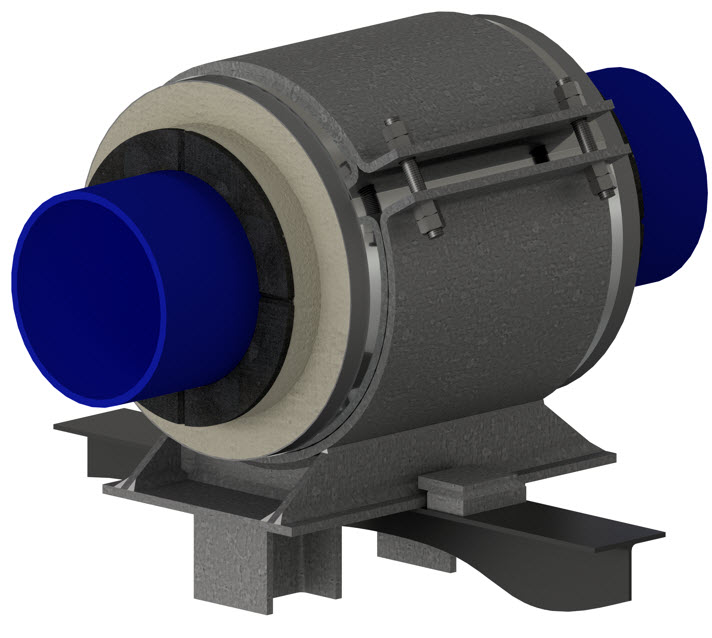

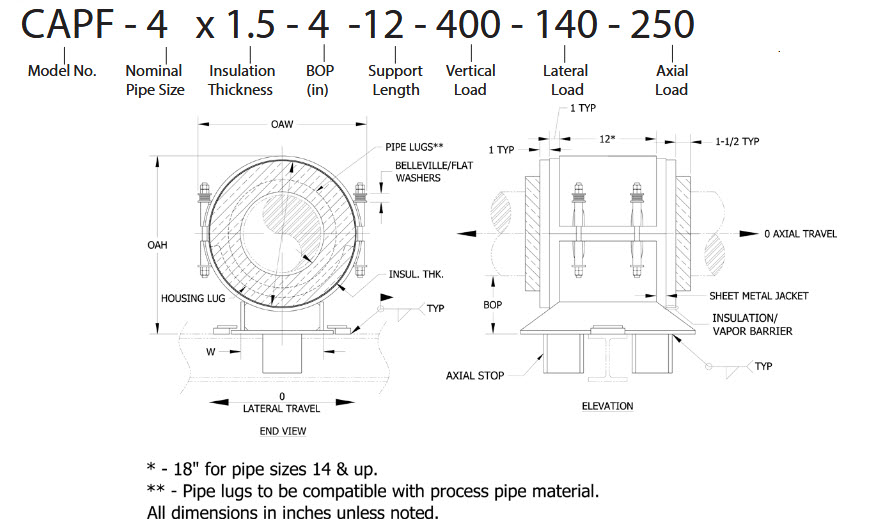

Anchored

Product Details (Model # CA-4000)

Additional Models

Application & Features

- Resists axial, vertical, and/or lateral pipe load

- Support supplied with guide angles and axial stops

- Temperature range: from -425° F to 275° F

- Higher temperature applications available

- Teflon®/2B SS304 slide plates on shoe and supporting steel

- Design loads based on a safety factor of 5

- A36 Steel construction

- See technical specification RHS-750

- Test results available upon request

- Steel finish available in galvanized or painted finishes

- Support features high density water blown polyurethane with vapor barrier

- Support constructed in accordance with ASME B31.1, B31.3 and MSS-SP58

- Exposed surfaces of polyurethane are coated with monolar mastic

- Support supplied with structural lateral restraint

- A307 or A193 B7 Plated bolts/studs

Required data when ordering

- Part Number

- Pipe Size

- Insulation Thickness

- Vertical Load

- Lateral & Axial Movements

- Operating Temperature

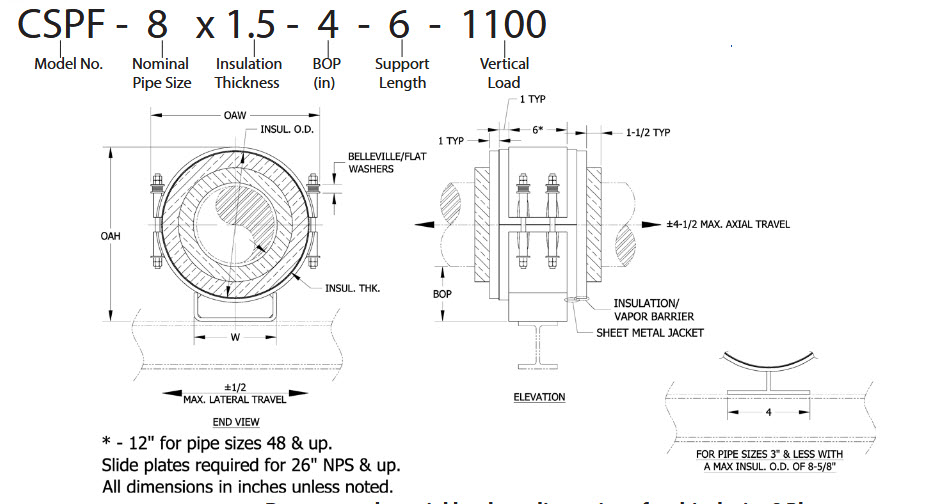

Sliding

Product Details

Application & Features

- Accommodates axial travel up to 3” if shoe is offset from supporting steel

- Temperature range: from -425° F to 275° F

- Higher temperature applications available

- Teflon®/2B SS304 slide plates on shoe and supporting steel

- Design loads based on a safety factor of 5

- A36 Steel construction

- See technical specification RHS-750

- Test results available upon request

- Steel finish available in galvanized or painted finishes

- Support features high density water blown polyurethane with vapor barrier

- Support constructed in accordance with ASME B31.1, B31.3 and MSS-SP58

- Exposed surfaces of polyurethane are coated with monolar mastic

- Support supplied with structural lateral restraint

- A307 or A193 B7 Plated bolts/studs

Required data when ordering

- Part Number

- Nominal Pipe Size

- Insulation Thickness

- Vertical Load

- Lateral & Axial Movements

- Operating Temperature

Guided

Product Details

Application & Features

- Accommodates axial travel up to 3” if shoe is offset from supporting steel

- Accommodates lateral load up to 50% of actual vertical load

- Temperature range: from -425° F to 275° F

- Higher temperature applications available

- Teflon®/2B SS304 slide plates on shoe and supporting steel

- Design loads based on a safety factor of 5

- A36 Steel construction

- See technical specification RHS-750

- Test results available upon request

- Steel finish available in galvanized or painted finishes

- Support features high density water blown polyurethane with vapor barrier

- Support constructed in accordance with ASME B31.1, B31.3 and MSS-SP58

- Exposed surfaces of polyurethane are coated with monolar mastic

- Support supplied with structural lateral restraint

- A307 or A193 B7 Plated bolts/studs

Required data when ordering

- Part Number

- Pipe Size

- Insulation Thickness

- Vertical Load

- Lateral & Axial Movements

- Operating Temperature

Anchored

Product Details

Application & Features

- Resists axial, vertical, and/or lateral pipe load

- Support supplied with guide angles and axial stops

- Temperature range: from -425° F to 275° F

- Higher temperature applications available

- Teflon®/2B SS304 slide plates on shoe and supporting steel

- Design loads based on a safety factor of 5

- A36 Steel construction

- See technical specification RHS-750

- Test results available upon request

- Steel finish available in galvanized or painted finishes

- Support features high density water blown polyurethane with vapor barrier

- Support constructed in accordance with ASME B31.1, B31.3 and MSS-SP58

- Exposed surfaces of polyurethane are coated with monolar mastic

- Support supplied with structural lateral restraint

- A307 or A193 B7 Plated bolts/studs

Required data when ordering

- Part Number

- Pipe Size

- Insulation Thickness

- Vertical Load

- Lateral & Axial Movements

- Operating Temperature