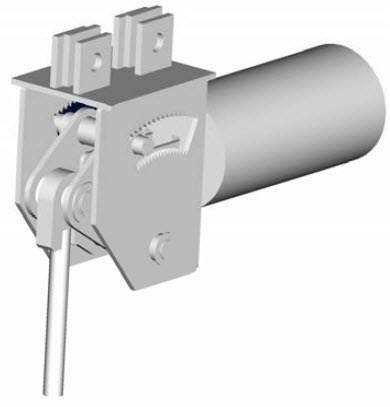

Constant Spring Supports

Constant springs are used to support piping whose movements and/or loading conditions cause too great a variability or too high of a loading condition for a variable spring. A

perfect constant support will exert the same lifting effort as the pipe moves either up or

down.

The geometric design of the constant support provides a mathematically constant amount of force exerted throughout the entire range of travel. The force is made constant by a counterbalancing spring assembly. This counterbalancing spring assembly is made up of a spring coil(s) and a set of levers.

As the levers move from the higher to the lower position, or vice versa, a turning moment about the main pivot is created that is both equal and opposite to the turning moment of the load and the load moment arms. As the lever moves from the higher to the lower position, the load spring is compressed, and the ensuing increased force causes the turning moment to be created. It is the opposite for the lever moving from the lower to the higher position. When the load spring is relaxed and the ensuing decreased force causes the turning moment to be created.

The formula F x A = R x B, can be used to illustrate this concept

F = Spring Force

A = Length of the Moment Arm from the

Spring Rod to the Main Pivot.

R = Supporting Force (pipe load)

B = Length of the Moment Arm of the Sup-

porting Force to the Main Pivot

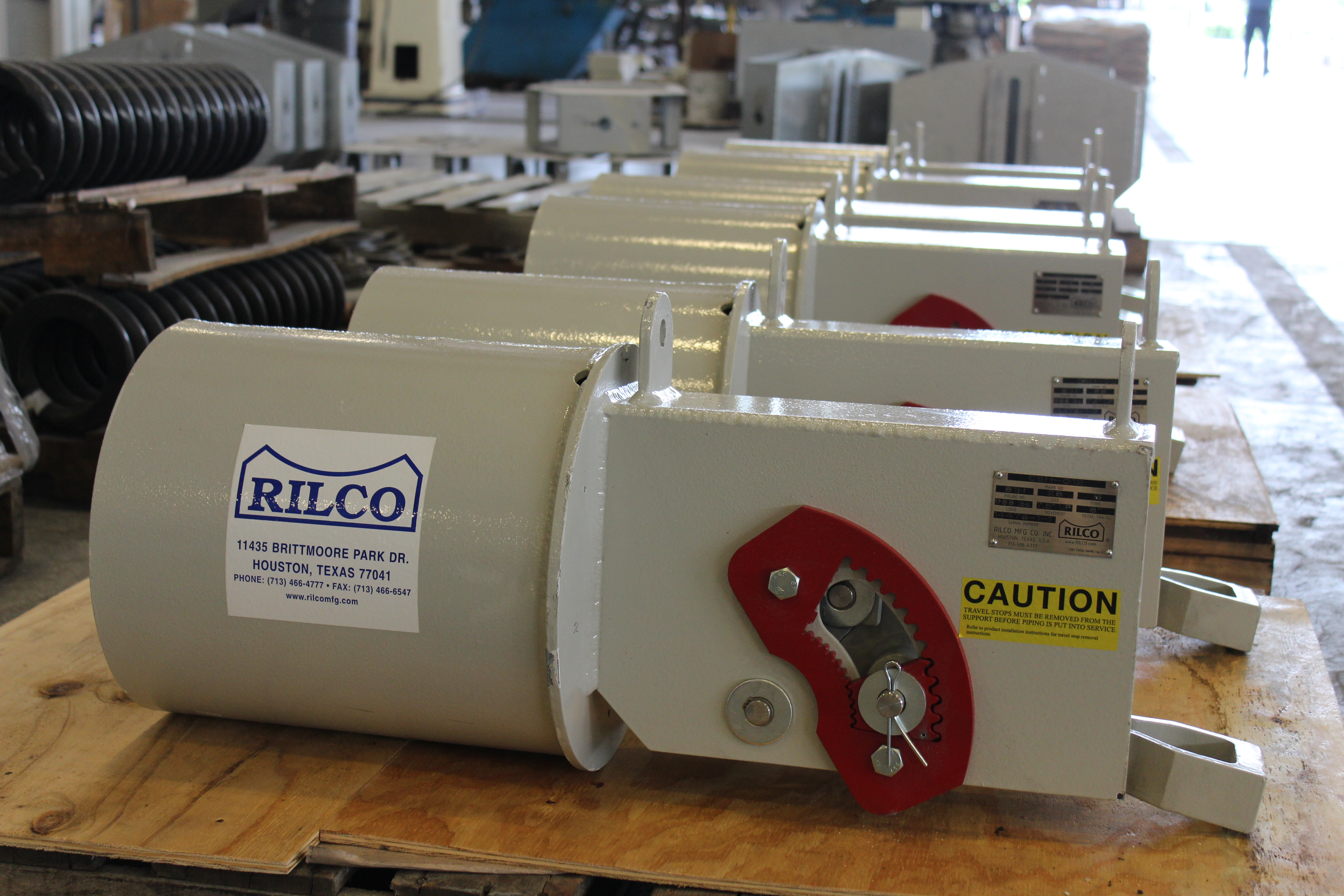

Design Features - Standard

- High load and travel capabilities

- Each hanger is calibrated independently to the customer’s specific load prior to shipment

- Designed to provide a more condensed and versatile unit

- Load is adjustable +/- 10% from the “as shipped” load

- Permanently installed rivets represent hot (red) and cold (white) positions

- Hot-dip galvanized finish per ASTM A153 protects the unit from corrosive and climactic conditions. The spring is powder-coated to provide additional protection for the coil.

- The spring cover prevents foreign objects from restricting the action of the coil spring while providing a clean functional appearance.

- Full range of travel, including over-travel stop placement enables blocking of the constant in nearly any position of the travel.

- Stainless steel shafts used in all locations subject to movement, ensures the unit will not seize due to corrosion

Design Features - Optional

- Lifting lugs are available for all sizes

- Optional finishes ranging from zinc-rich primer to powder-coating for casing and components

- Units fabricated entirely from stainless steel, including the coil are available by special order

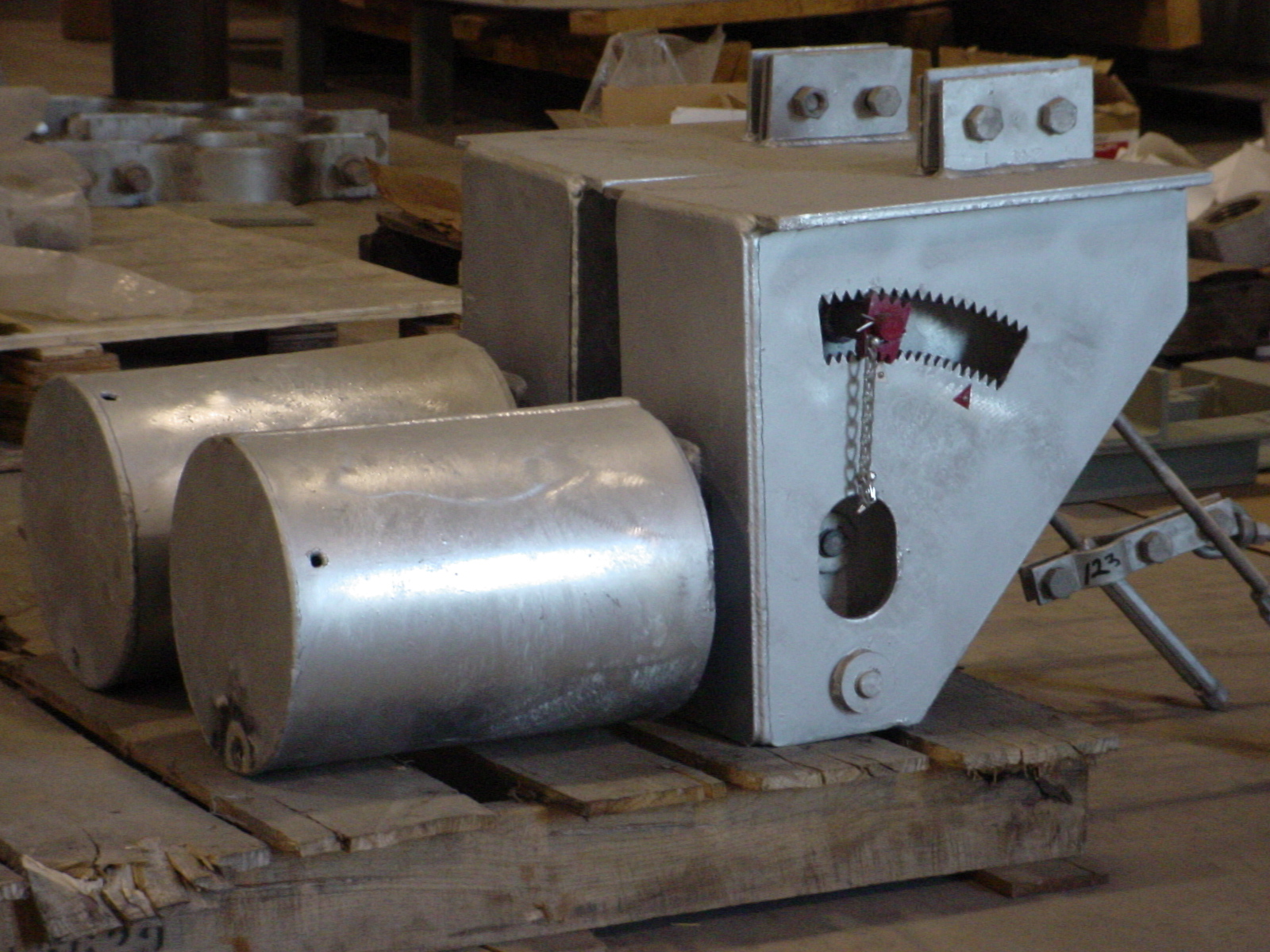

Limit and Travel Stops

RILCO constant supports have built-in upper and lower limit stops to restrict the travel, avoiding damage to the support. The ends of the travel arc are specifically located to act as the limit stops when the movement causes the stop shaft the contact them. The travel stops are painted RED “toothed”

on both sides with a hole in the center, in order to allow placement in multiple locations along the travel arc. The stops are placed on the stop shaft and retained with either clips or cotter pins. The stops are to (MUST) be removed prior to the line being put into service. Reference the installation instructions for the proper sequencing of events prior to retainer removal.

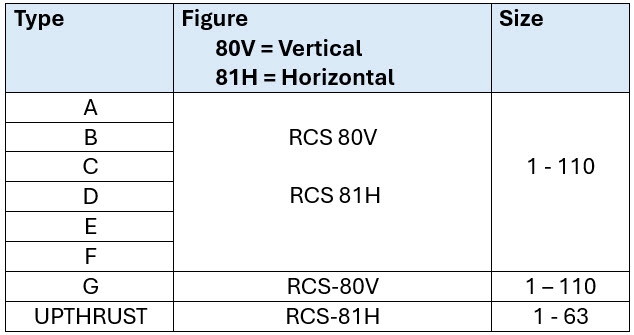

Type, Figure & Size Chart

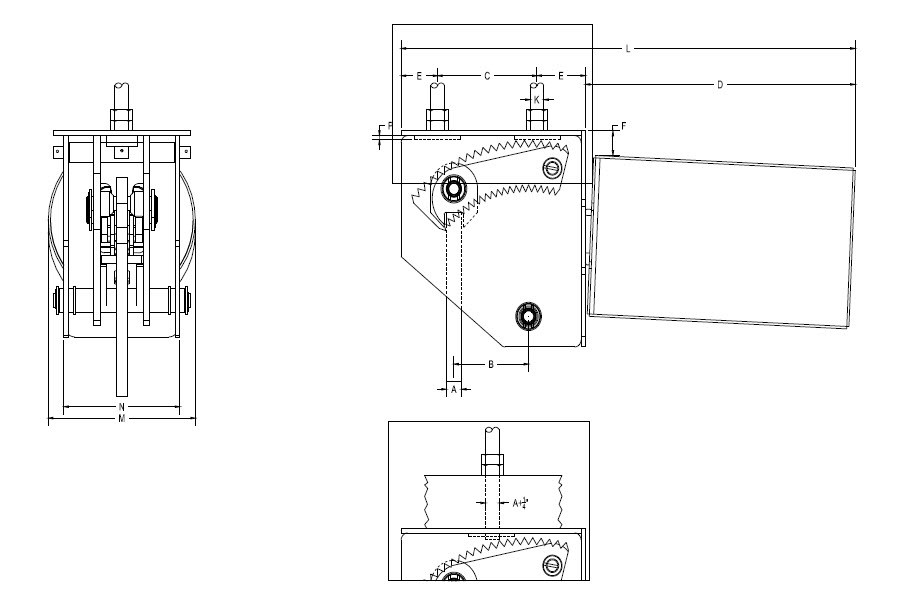

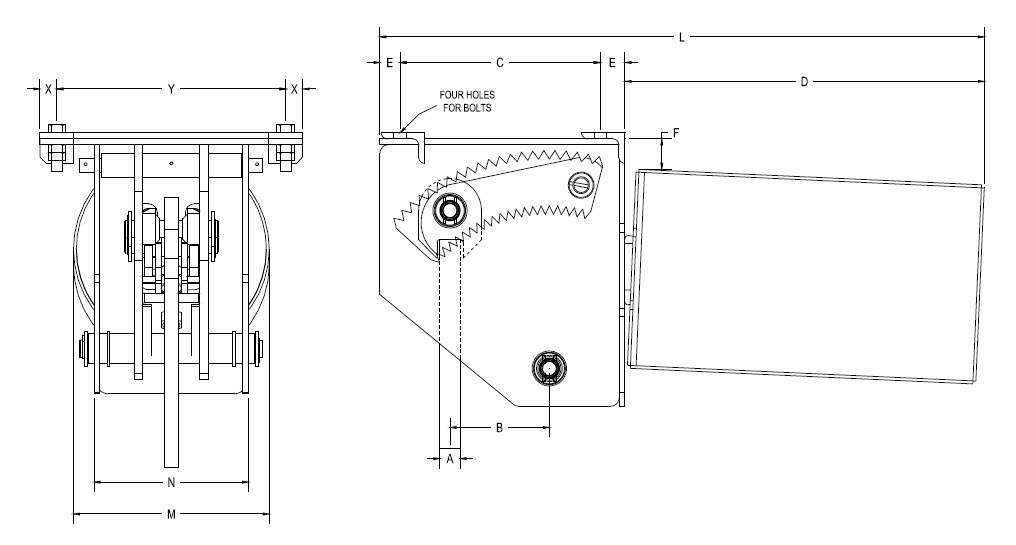

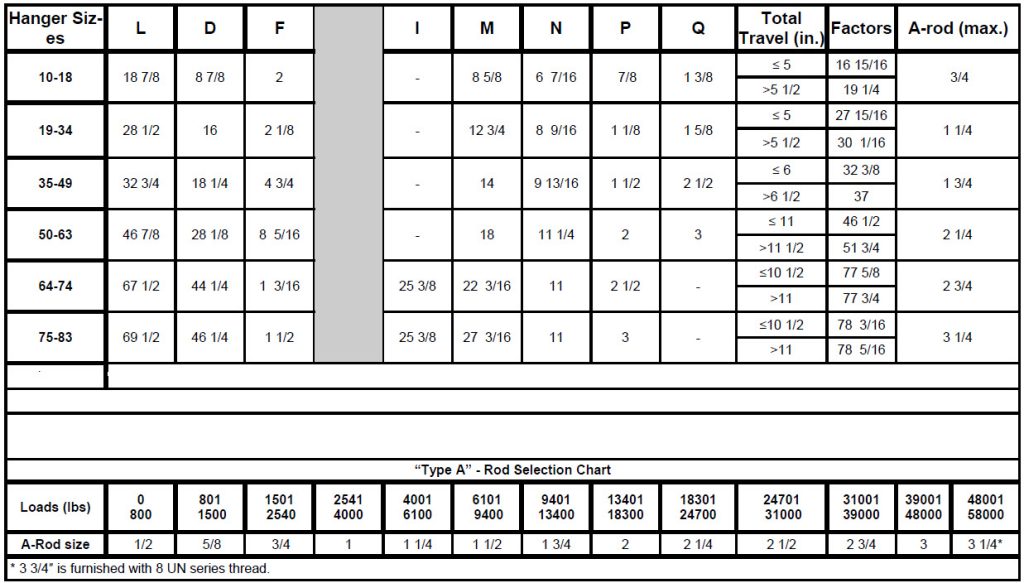

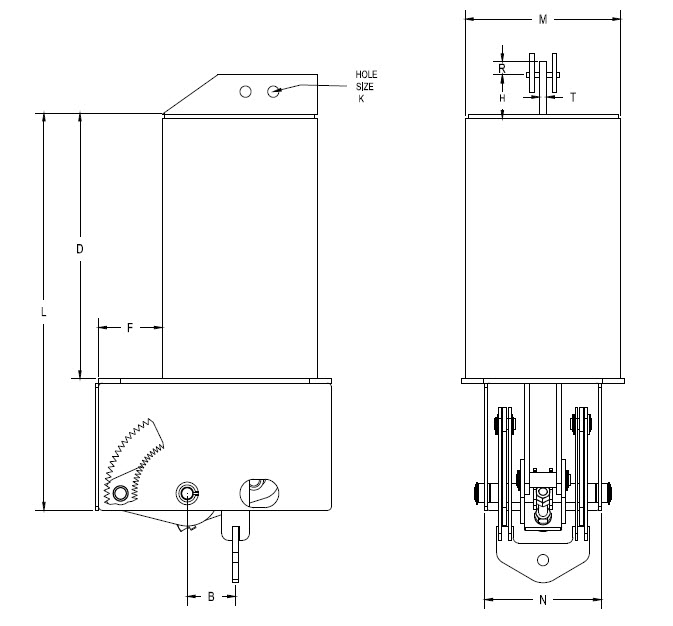

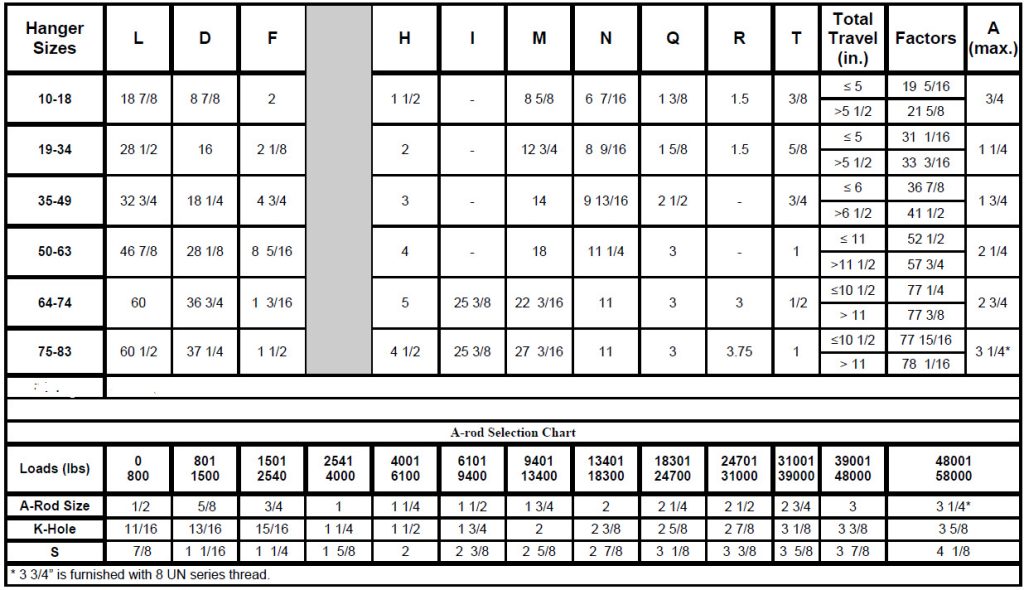

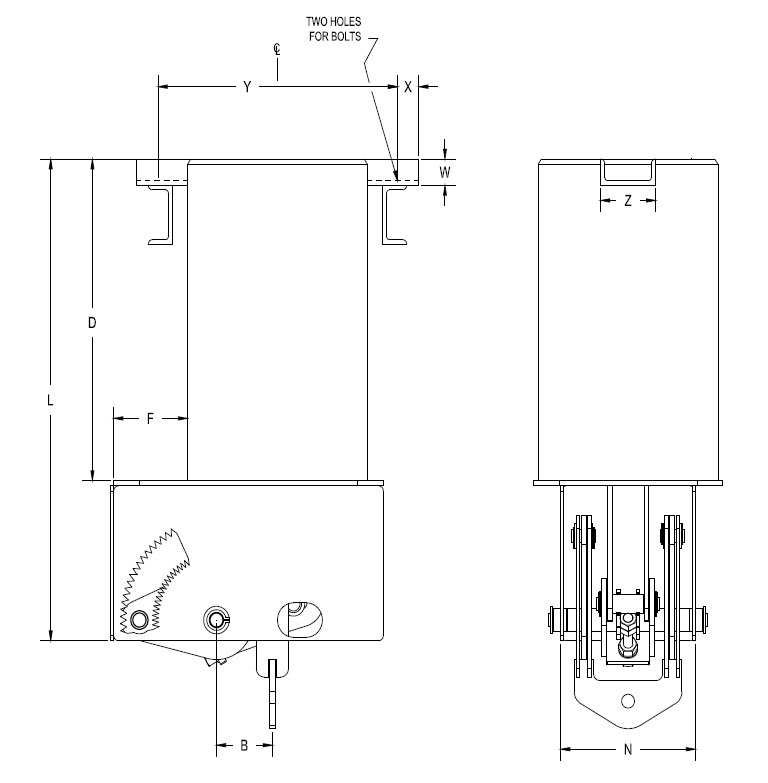

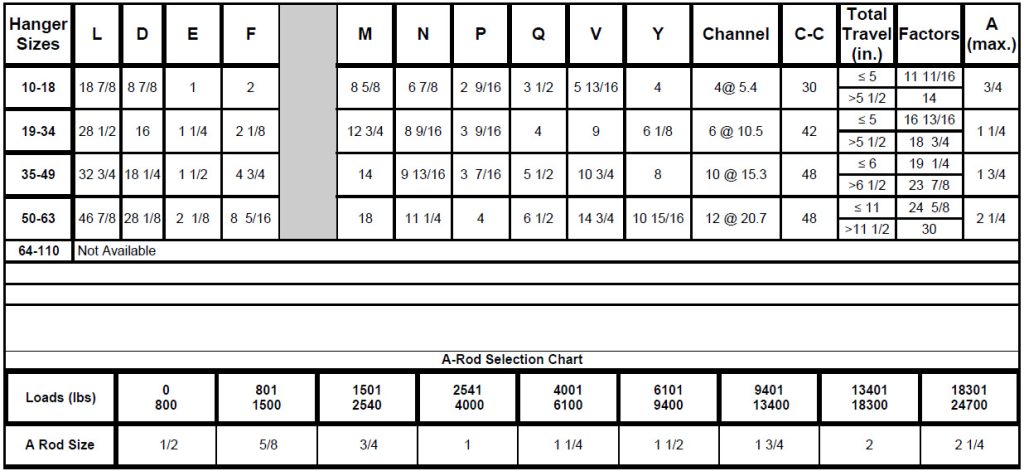

A Type

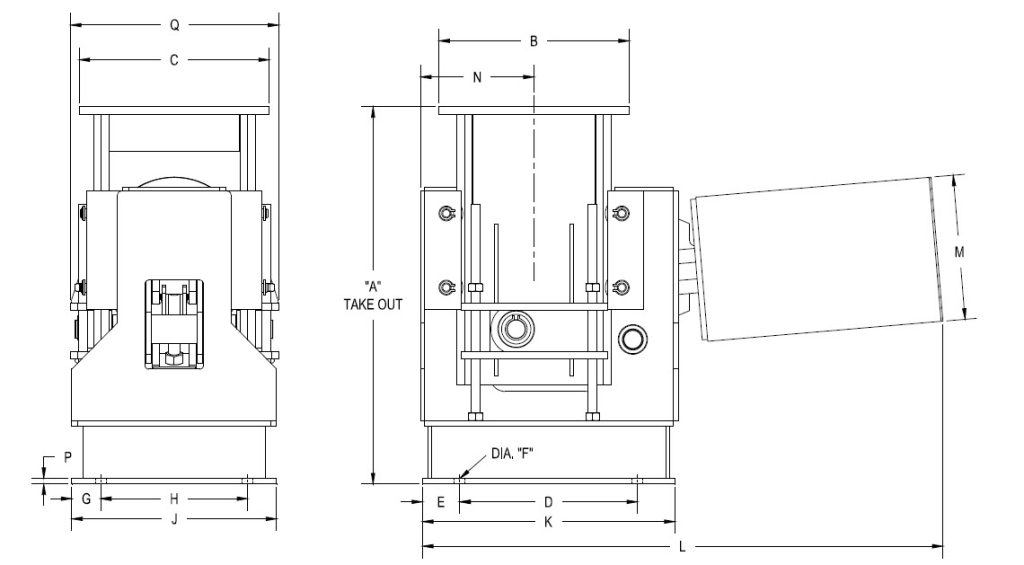

The RCS-81H “TYPE A” is specially designed for mounting on a supporting member by means of attaching two (2) rods into the tapped holes in the constant support’s top cap. A distance equal to the “P” dimension plus 3/8”. Available in most types of finishes.

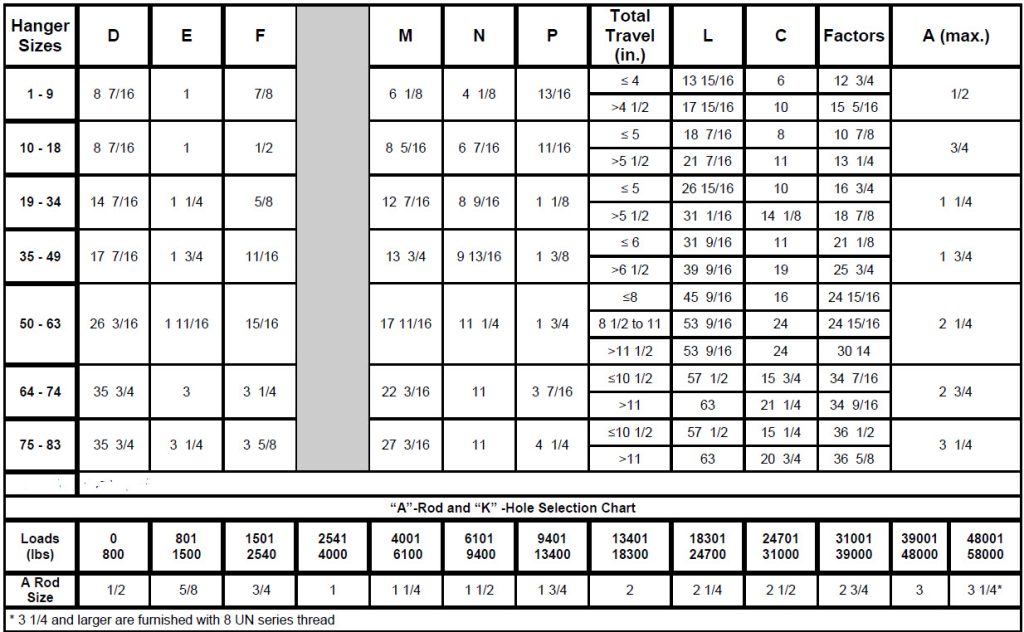

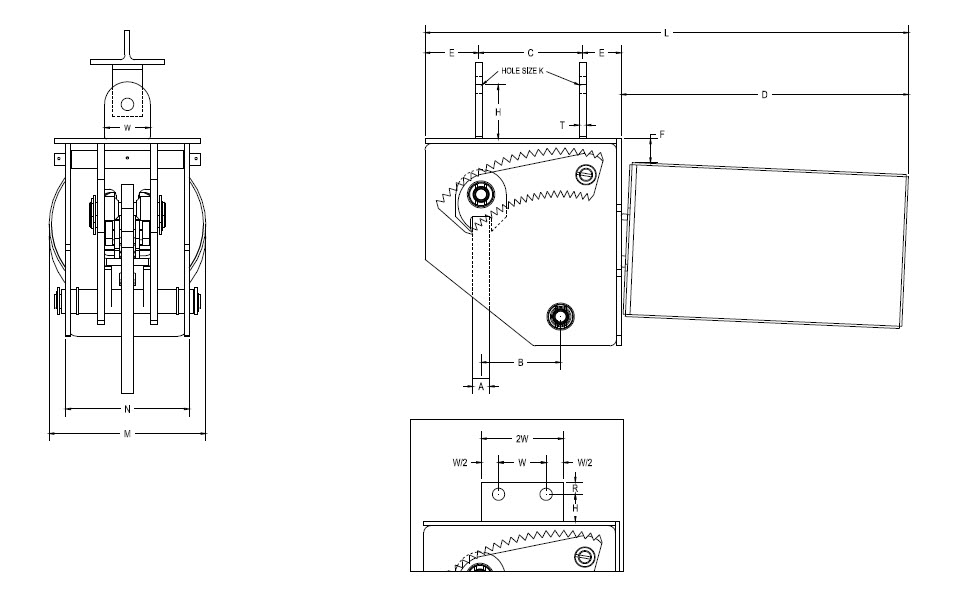

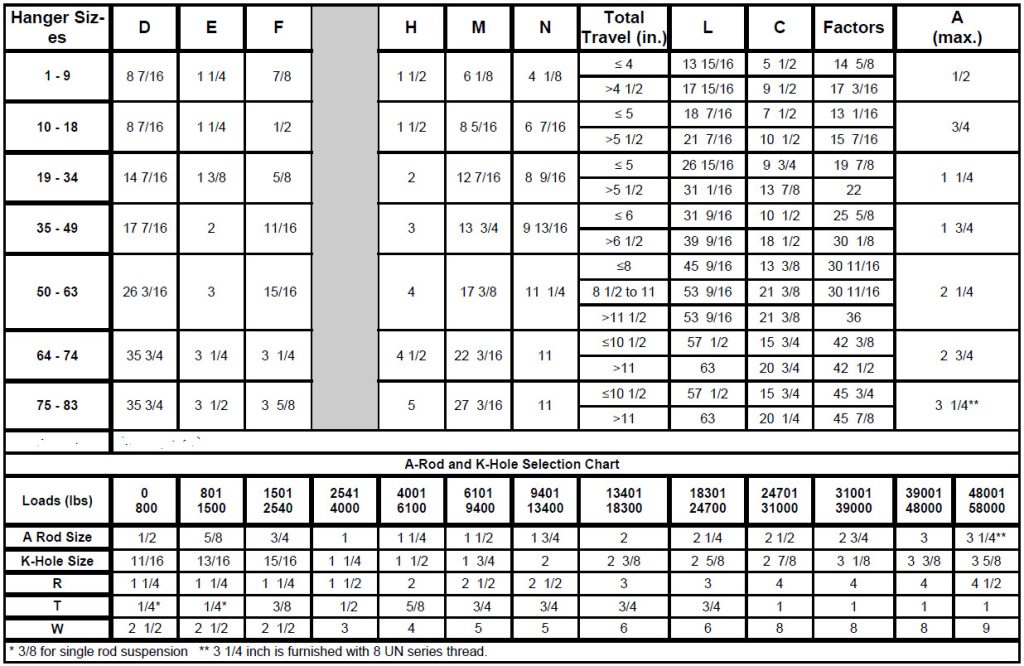

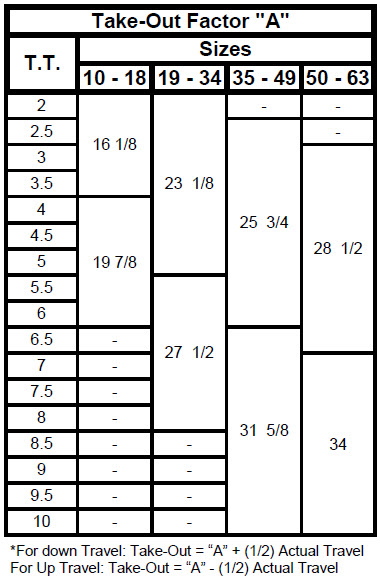

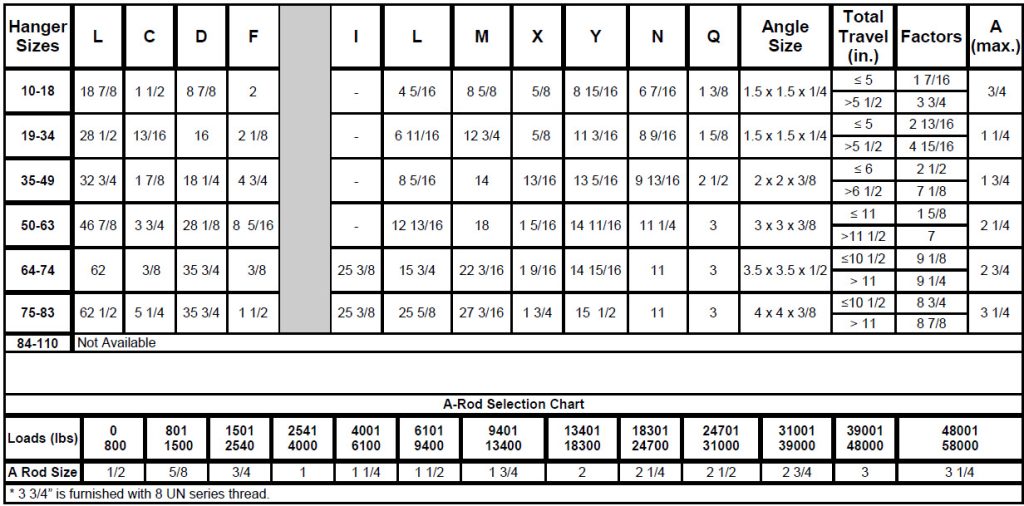

Use the chart below for dimensions of type A

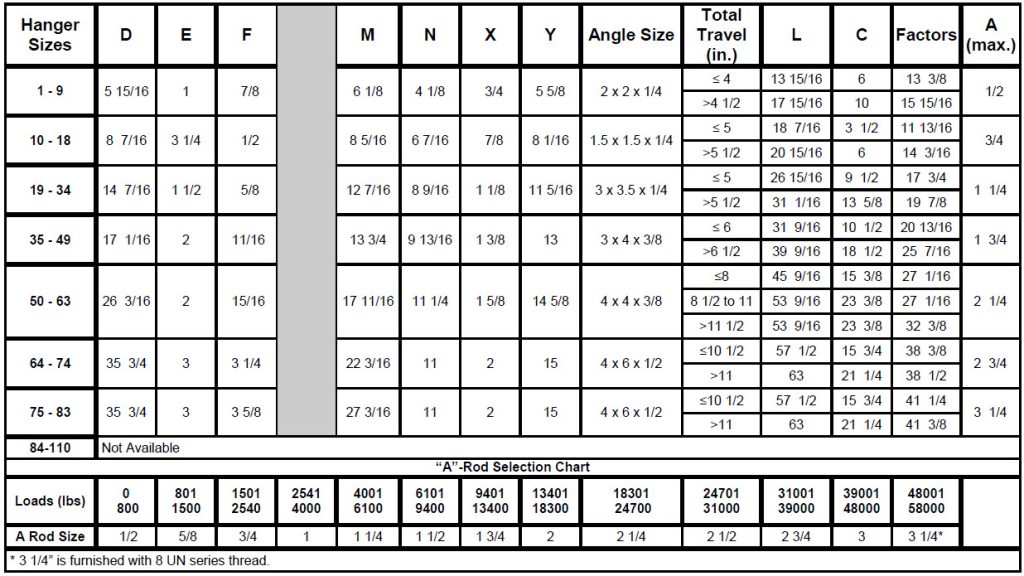

B Type

The RCS-81H “TYPE B” manufactured with two (2) lugs to accommodate attachment to the building structure and allowing for the use of various types of attachments. (Example: RILCO Part# 100, or Part# 290). Available in most types of finishes.

Use the chart below for dimensions of type B

C Type

The RCS-81H “TYPE C” manufactured using two (2) lugs to accommodate attachment to the building structure also allowing for the use of various types of attachments. (Example: RILCO Part# 220 ). Available in most types of finishes.

Use the chart below for dimensions of type C

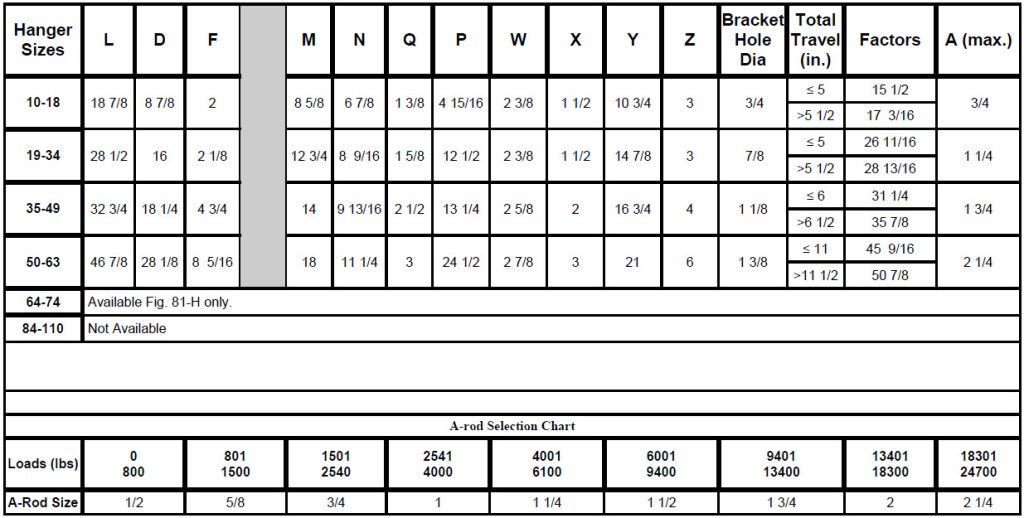

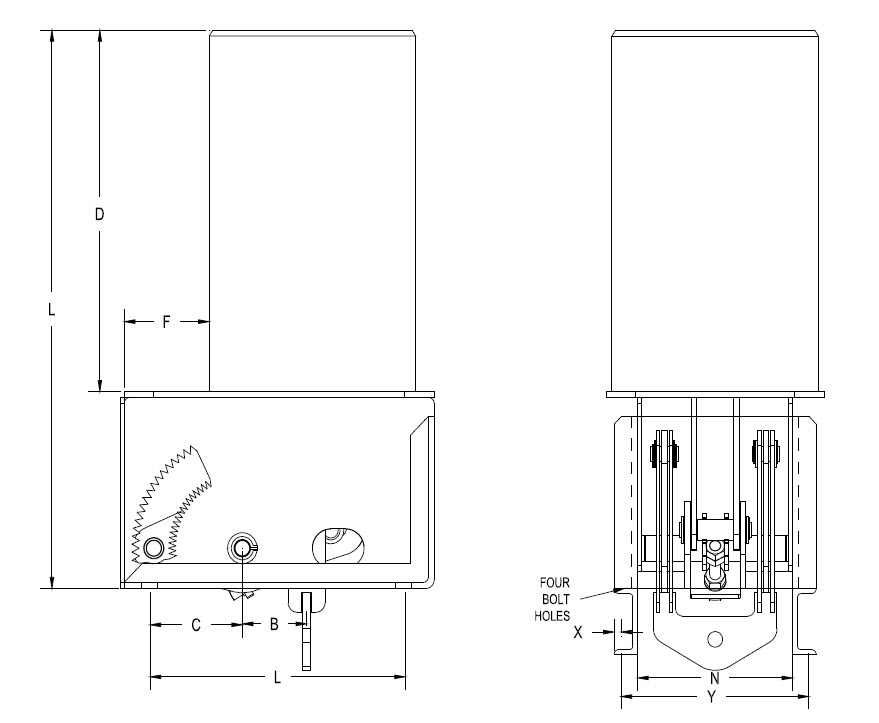

D Type

The RCS-81H “TYPE D” designed to be attached directly under the steel support member. Available in most types of finishes.

Use the chart below for dimensions of type D

E Type

The RCS-81H “TYPE E” is similar to “TYPE D” except that the “TYPE E” is designed using two (2) brackets welded to the support casing forming a frame which allows the unit to be attached to the

top of the structural support. Available in most types of finishes.

Use the chart below for dimensions of type E

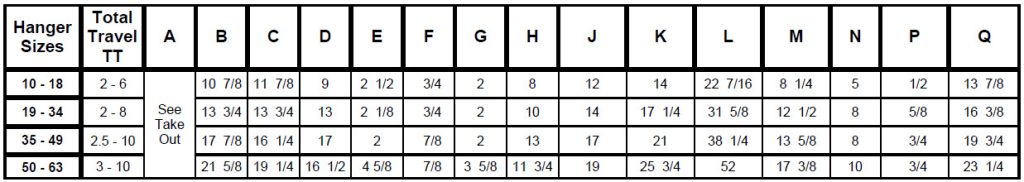

F Type (UPTHRUST)

The RCS-81H “TYPE F UPTHRUST” is specifically designed to support pipes or equipment from below and is supplied with a base to anchor it to the floor. Available in most types of finishes.

* For down travel:

Take-out= “A”+ (1/2) actual travel

For up travel:

Take-out=“A”- (1/2) actual travel

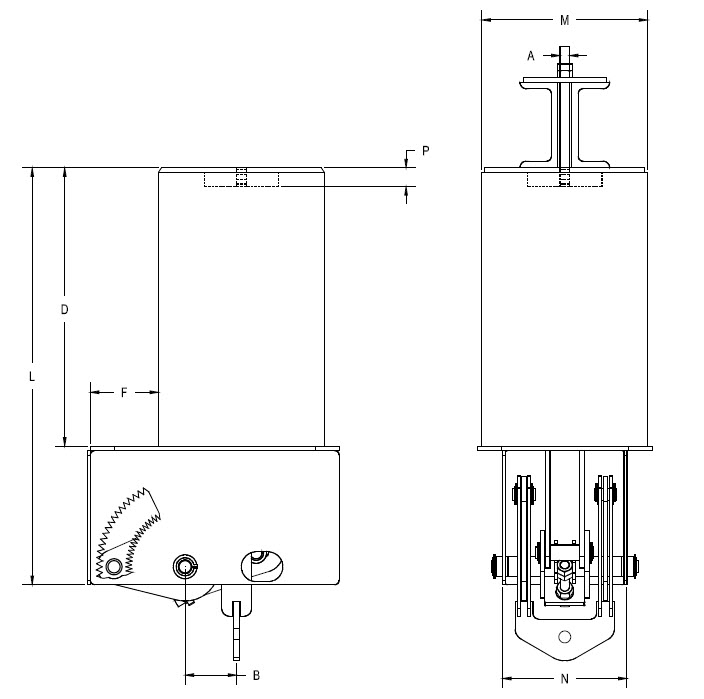

Use the chart below for dimensions of Upthrust

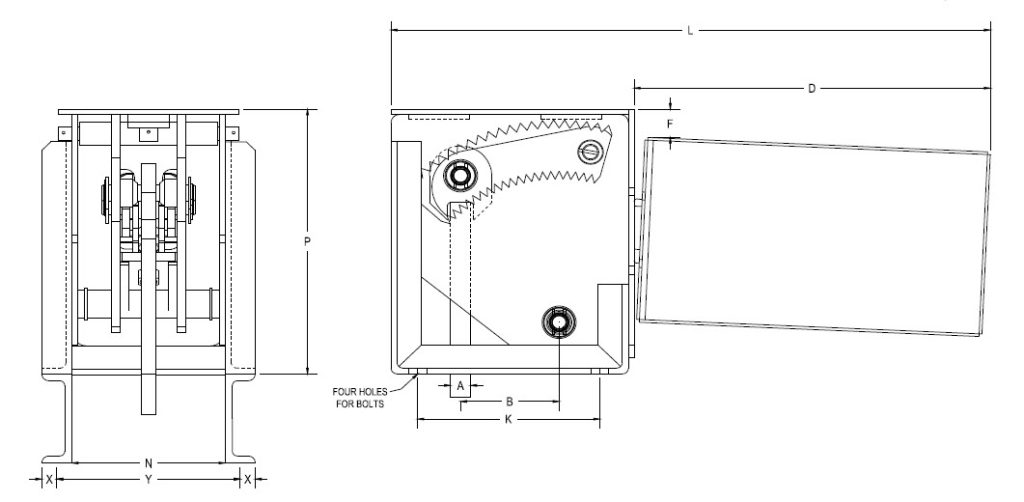

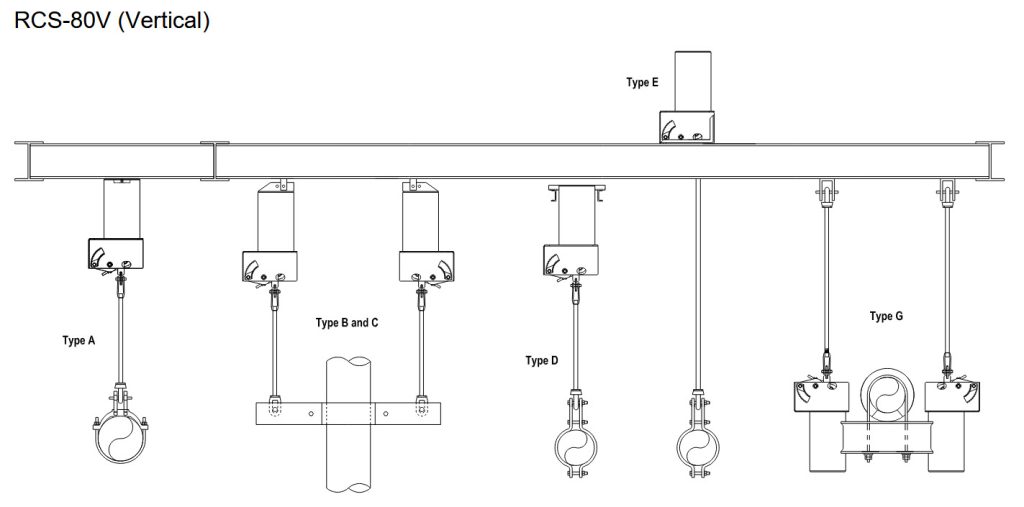

A Type

The RCS-80V “TYPE A” is specially fabricated for mounting on a supporting member by means of attaching a rod into the tapped hole in the constant support’s top cap. A distance equal to the “P” dimension plus 3/8”. Available in most types of finishes.

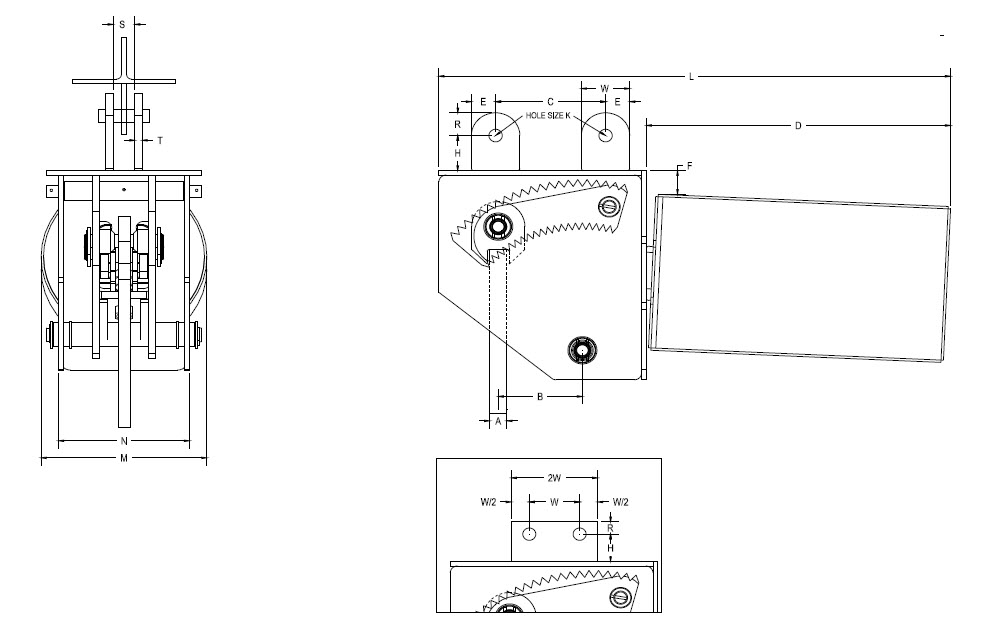

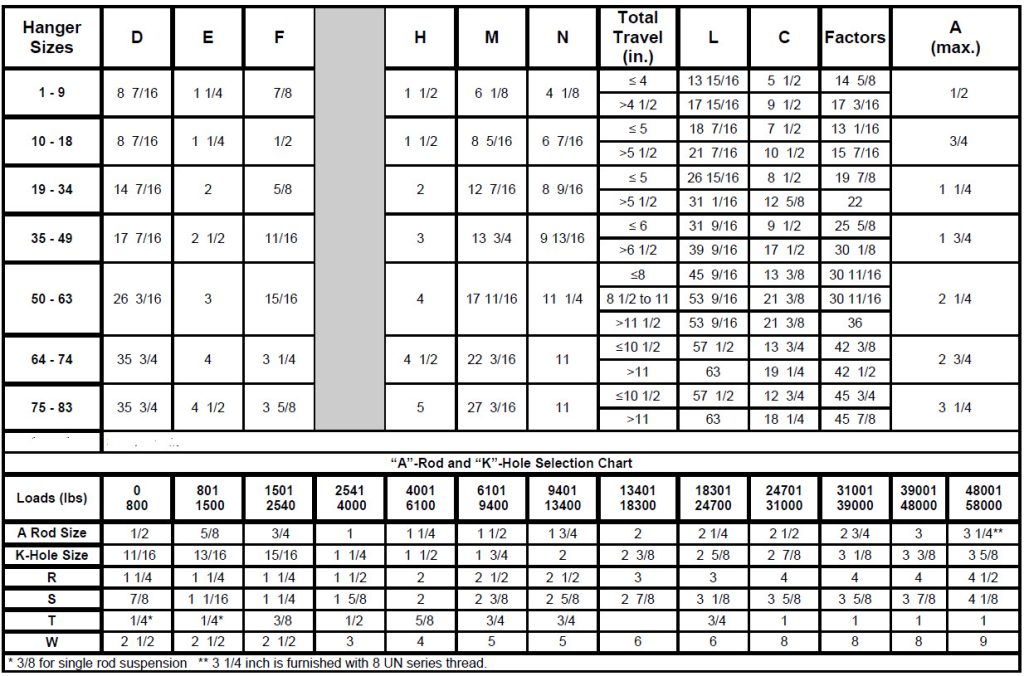

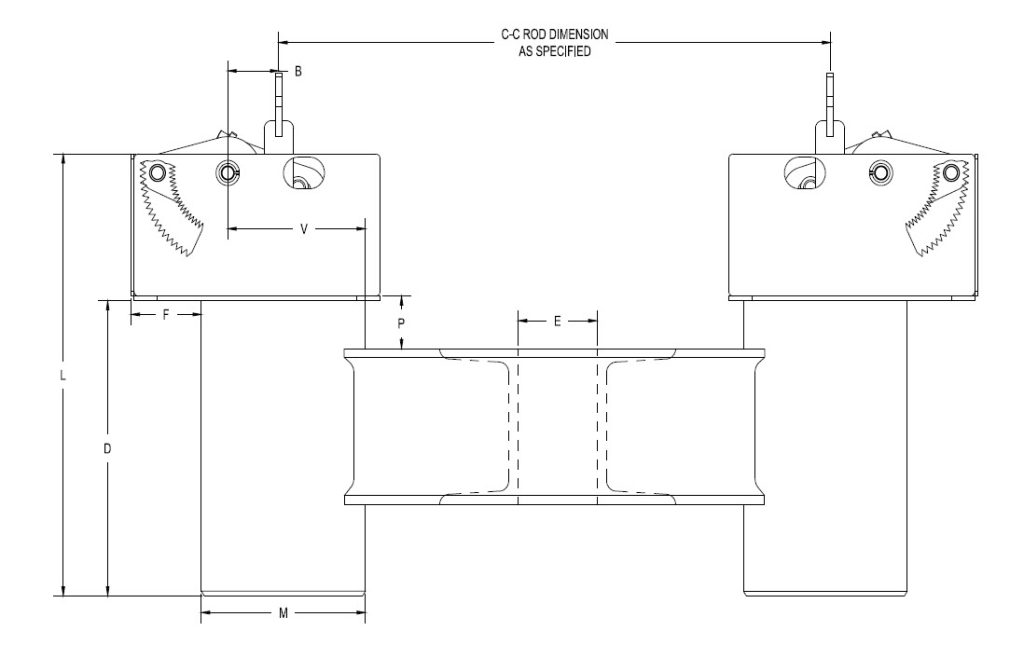

Use the chart below for dimensions of type A

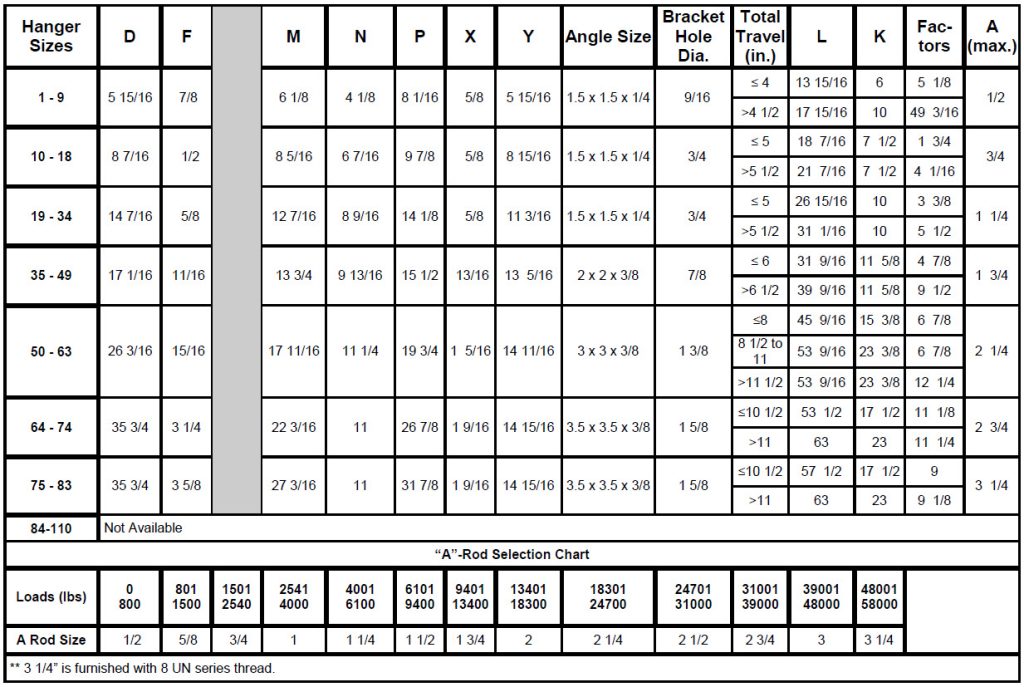

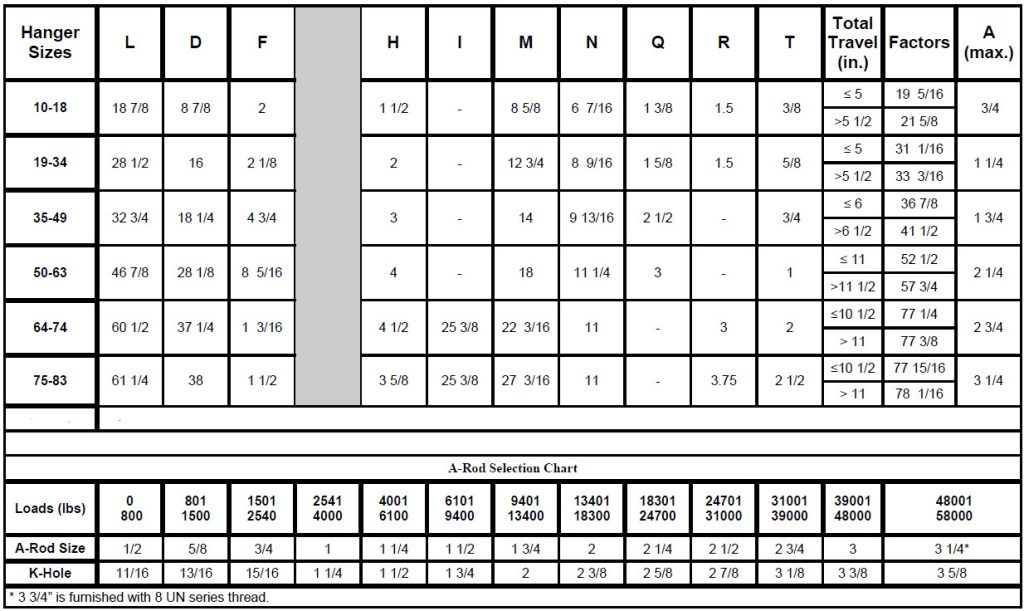

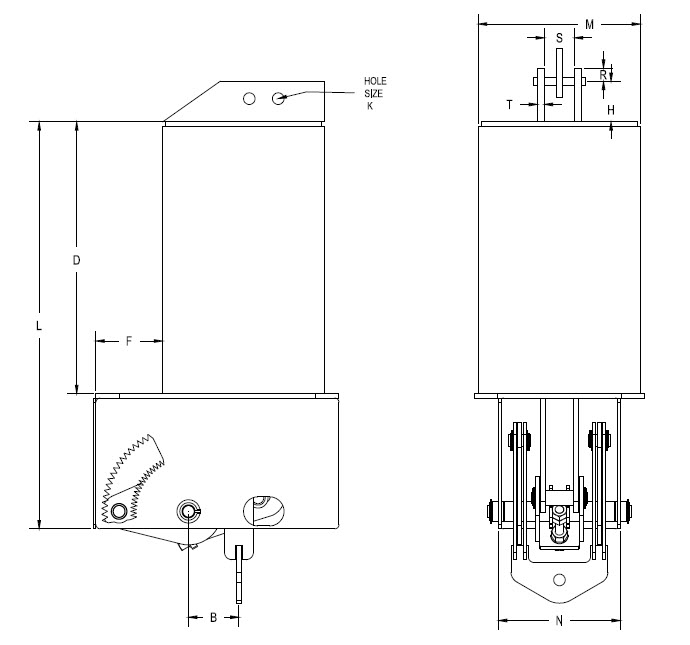

B Type

The RCS-80V “TYPE B” is manufactured with one lug to accommodate attachment to the building structure and allowing for

the use of various types of attachments. (Example: RILCO Part# 100, or Part# 290.) Available in most types of finishes.

Use the chart below for dimensions of type B

C Type

The RCS-80V “TYPE C” is manufactured using two(2) lugs to accommodate attachment to the building structure and allowing for the use of various types of attachments. (Example: RILCO Part#

220). Available in most types of finishes.

Use the chart below for dimensions of type C

D Type

The RCS-80V “TYPE D” is designed to lay on top of the beams or structural steel rather than attaching to the structures like the other “Constant Supports”. Available in most types of finishes.

Use the chart below for dimensions of type D

E Type

The RCS-80V “TYPE E” is the same as the RCS 80-V “TYPE D” except the “TYPE E” is designed with two (2) brackets that comprise its frame thereby allowing it to rest on the top flange of the structural

member. Available in most types of finishes.

Use the chart below for dimensions of type E

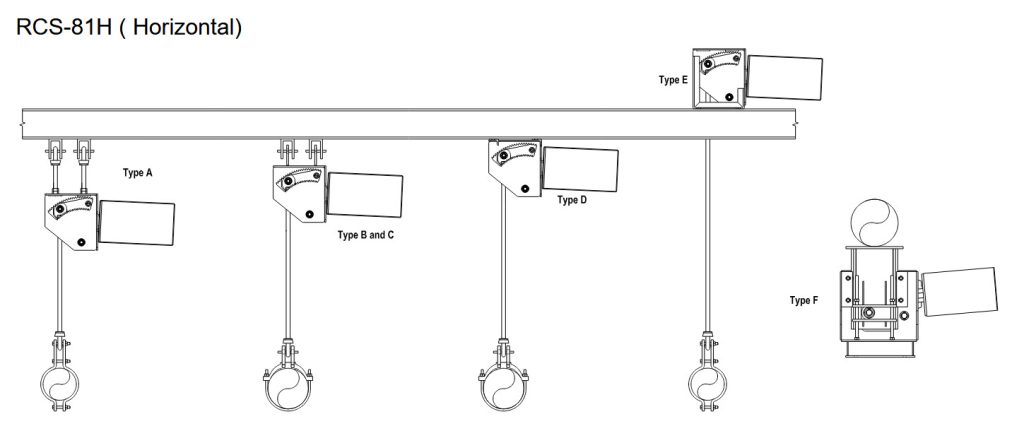

G Type

The RCS-80V “TYPE G” is manufactured using opposing constants and a pair of channels welded back-to-back, to form a trapeze assembly. This RILCO system is designed for use when a pipe is not to be centered on the constant support so that one spring of the trapeze carries a heavier load than the other. Available in most types of finishes.

Use the chart below for dimensions of type G

Selection of Type and Figure

The selection of a particular type and figure will be determined by the supporting steel and space conflicts with the surrounding objects. The figure RCS-81H is a horizontal arrangement which requires less headroom, but increased room horizontally. The RCS-80V is a vertical arrangement which requires more headroom, but less space horizontally. Types A, B, C, D, E and G are available in the RCS-80V and 81H series. Type F is available only in the RCS-81H series.

Special constant support configurations can be designed for unique applications.

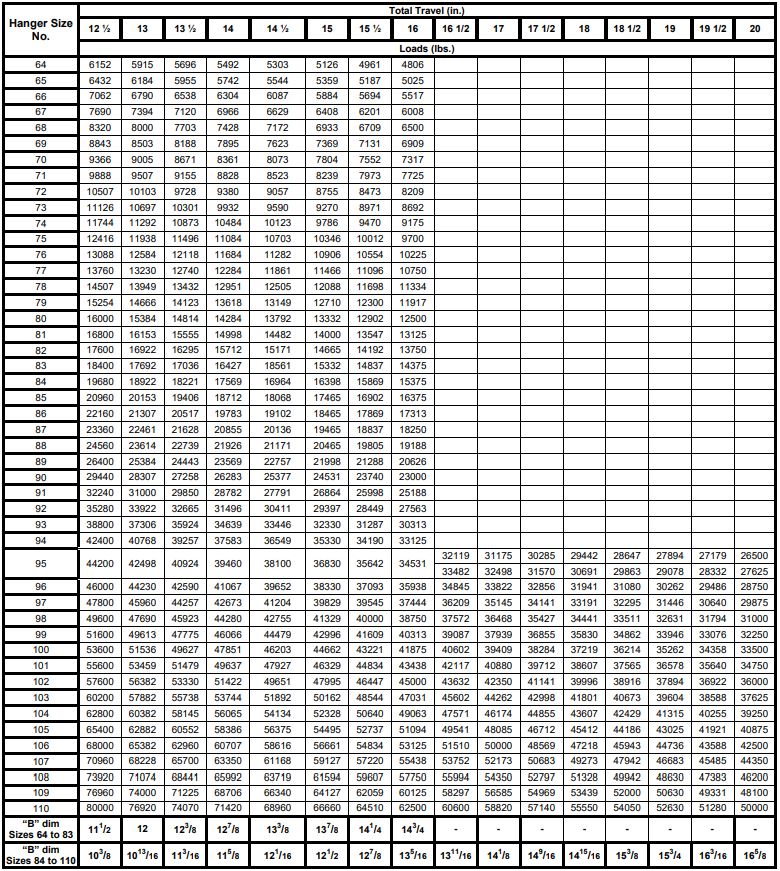

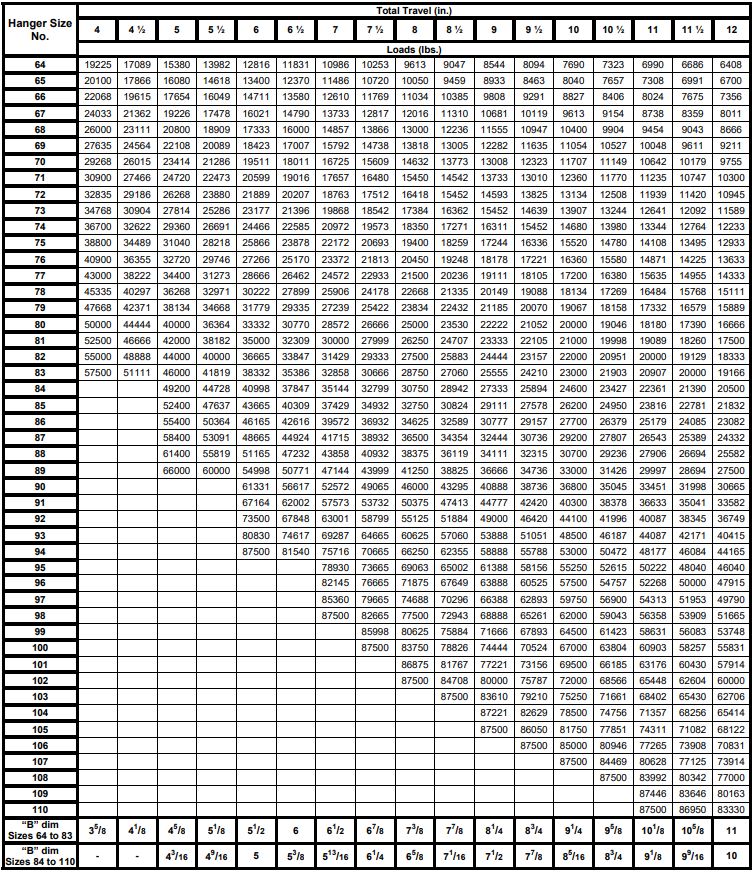

Selection of Support Size

RILCO manufactures constant supports in sizes with travels ranging from 1-1/2″ to 21″ and with loads from 25 to 87,500 pounds. Proper selection requires that the total load; including pipe thermal loads, working fluid, and hanger hardware, as well as the actual travel, or vertical movement of the pipe at the support location, be known. Please refer the accompanying constant support size chart to select a size which will accommodate both the load and the total travel. The total travel is designed to allow for differences between the calculated travel and the actual travel. The total travel is determined by adding 1″ or 20% of the actual travel, whichever is greater, to the calculated actual travel.